Introduction.

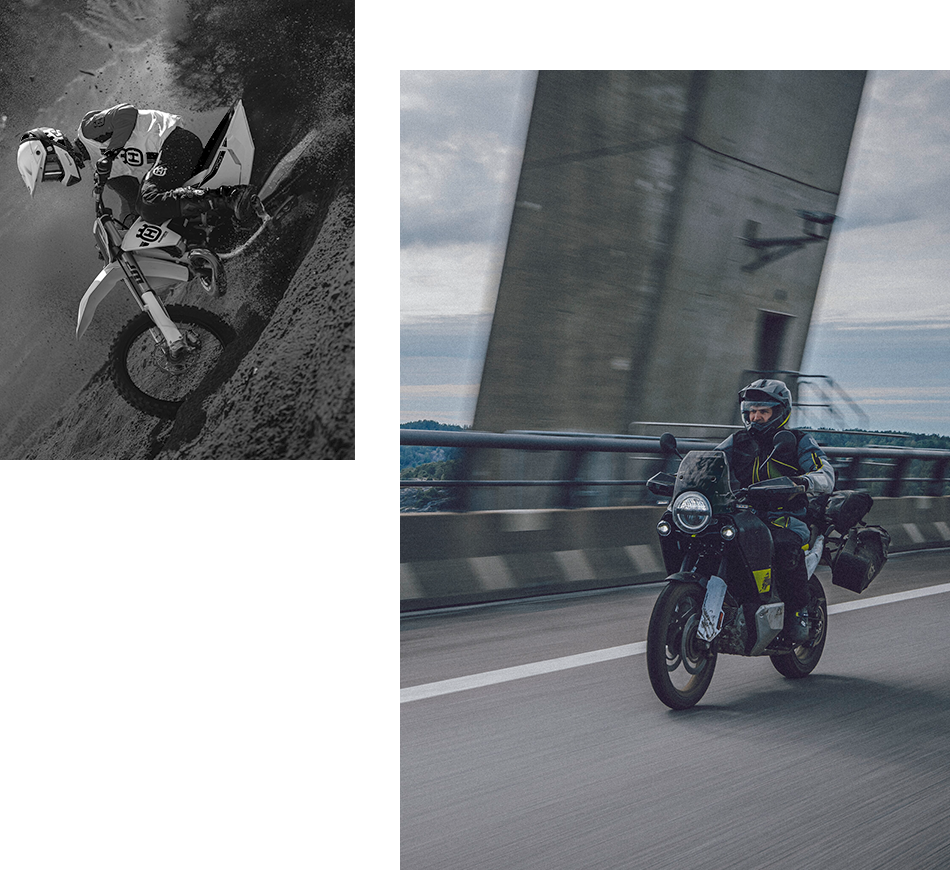

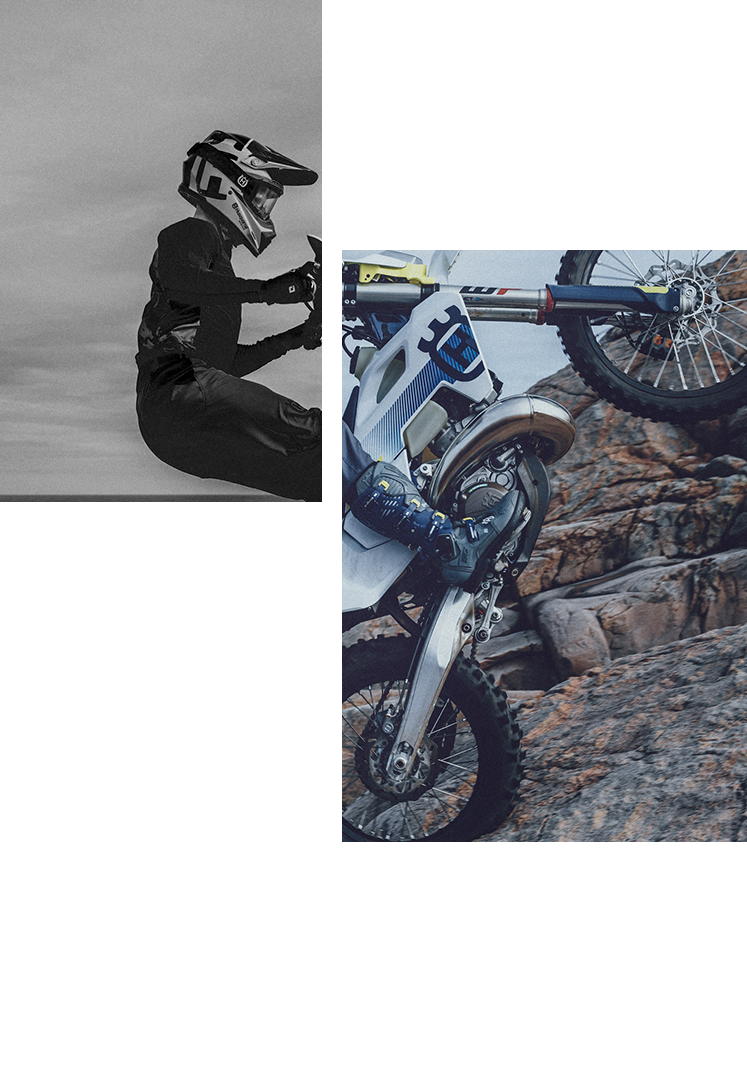

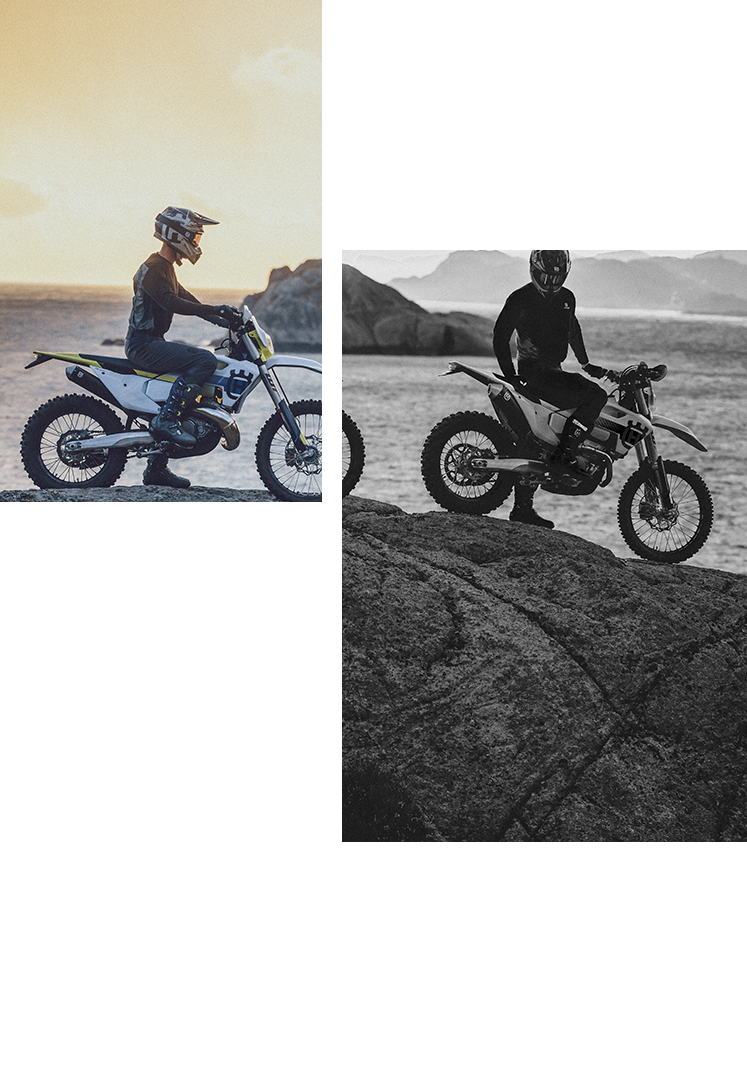

Husqvarna Motorcycles introduces its 2023 TE and FE enduro line-up, a range of seven 2-stroke and 4-stroke machines aimed at enduro riders of all levels of experience and skill. Dynamic performance and advanced ergonomics combine in the 2023 enduro range to deliver unrivalled power and handling to the competitive enduro rider.

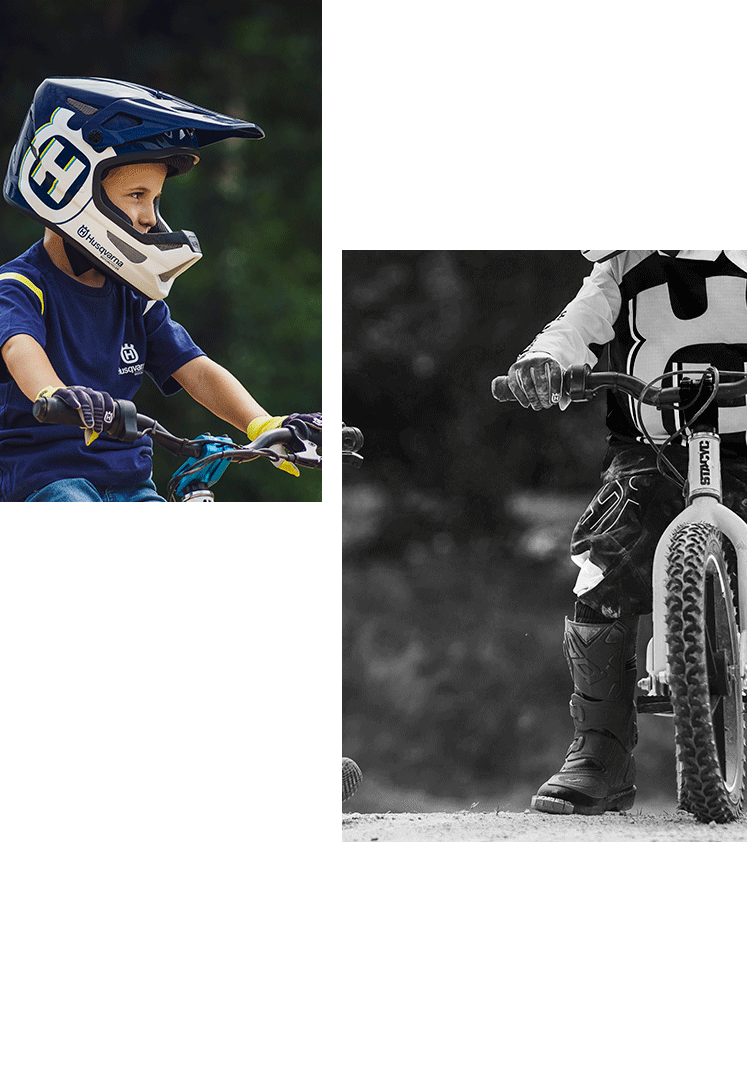

Riders of every level, from amateur to professional, will find a machine in a line-up unequalled in its sector for technical advancement and race-winning reliability and durability. The model range is made up of the TE 150, TE 250 and TE 300 2-strokes and the FE 250, FE 350, FE 450 and FE 501 4-strokes.

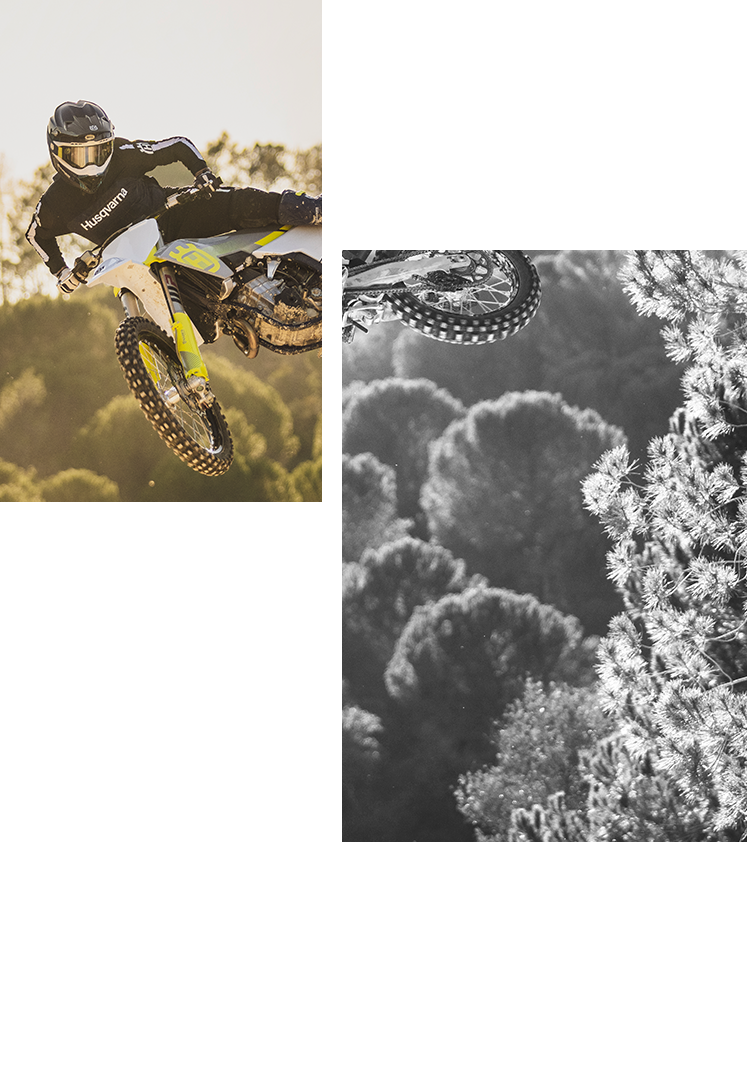

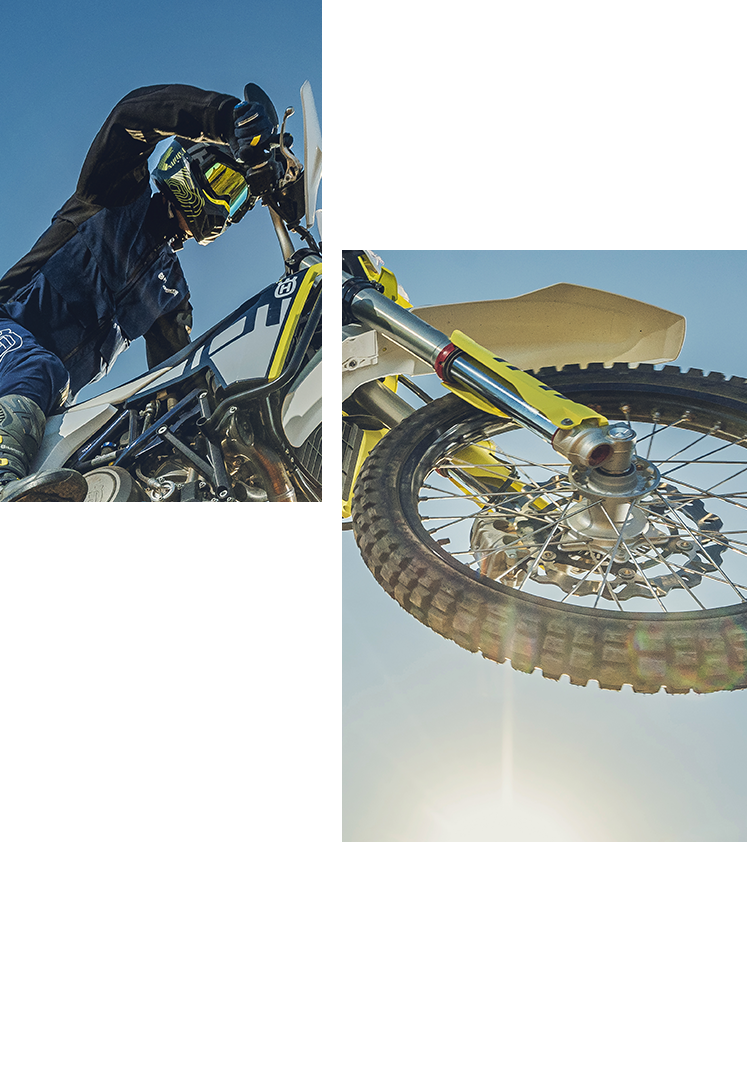

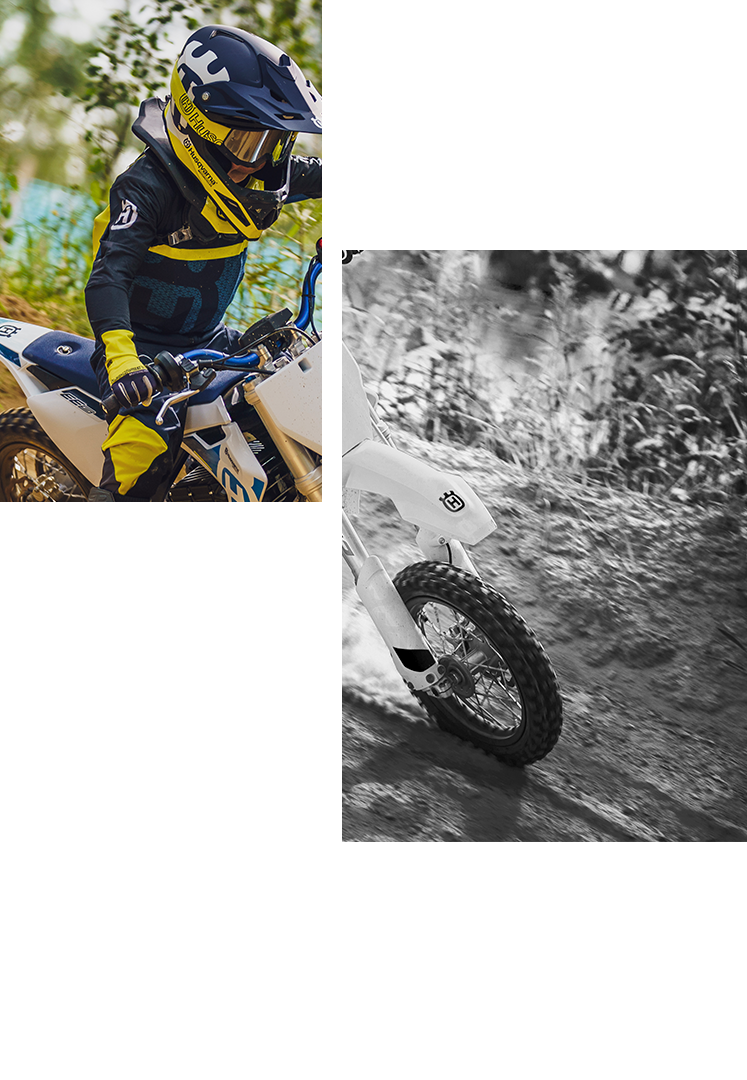

The enduro range has a number of attributes shared across all TE and FE models. A unique carbon composite subframe weighs just over 1 kg and aids handling and comfort, while the bodywork has narrow contact points for easy movement between riding positions. WP suspension is specified – an XPLOR 48mm front fork with split damping and easy access preload adjusters, and a rear shock with a motocross-developed progressive linkage and 300 mm of travel. By sharing BRAKTEC hydraulic braking and clutch systems, all models are guaranteed perfect clutch modulation in every condition, as well as superior stopping power with outstanding feel specifically tailored for enduro riding.

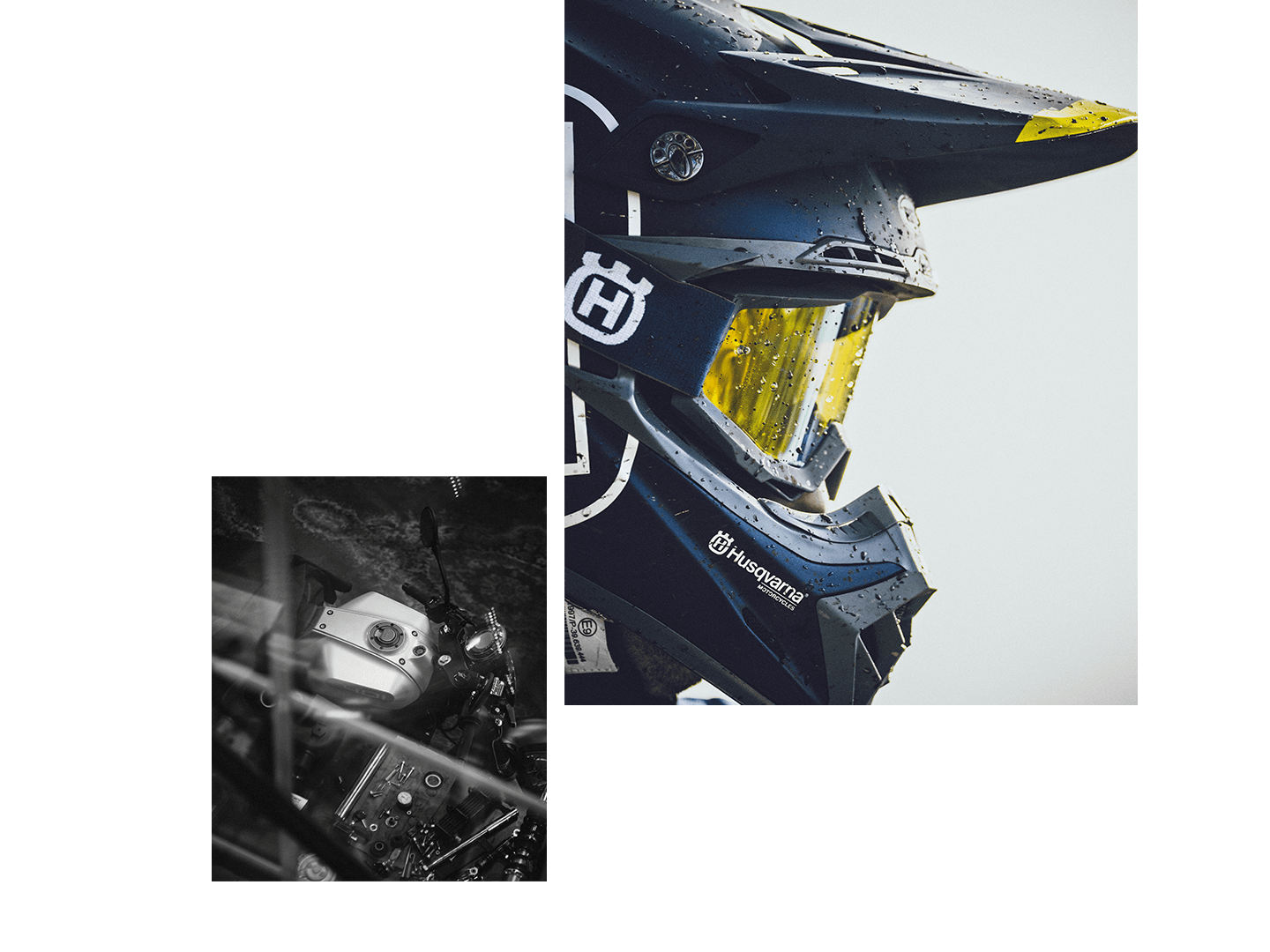

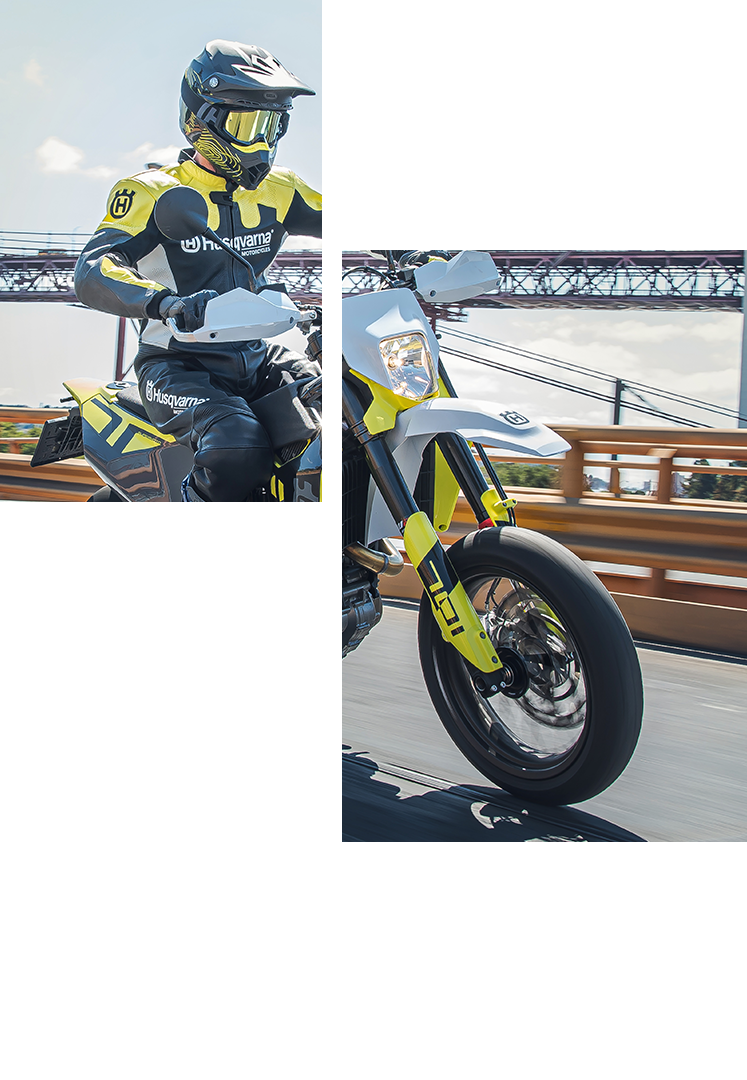

The winning intent of the 2023 enduro series is apparent in a new bodywork embodying Husqvarna Motorcycles’ progressive approach to Swedish-inspired offroad motorcycle design. Dark blue graphics with electric yellow accents use the familiar colours in all-new combinations for 2023.

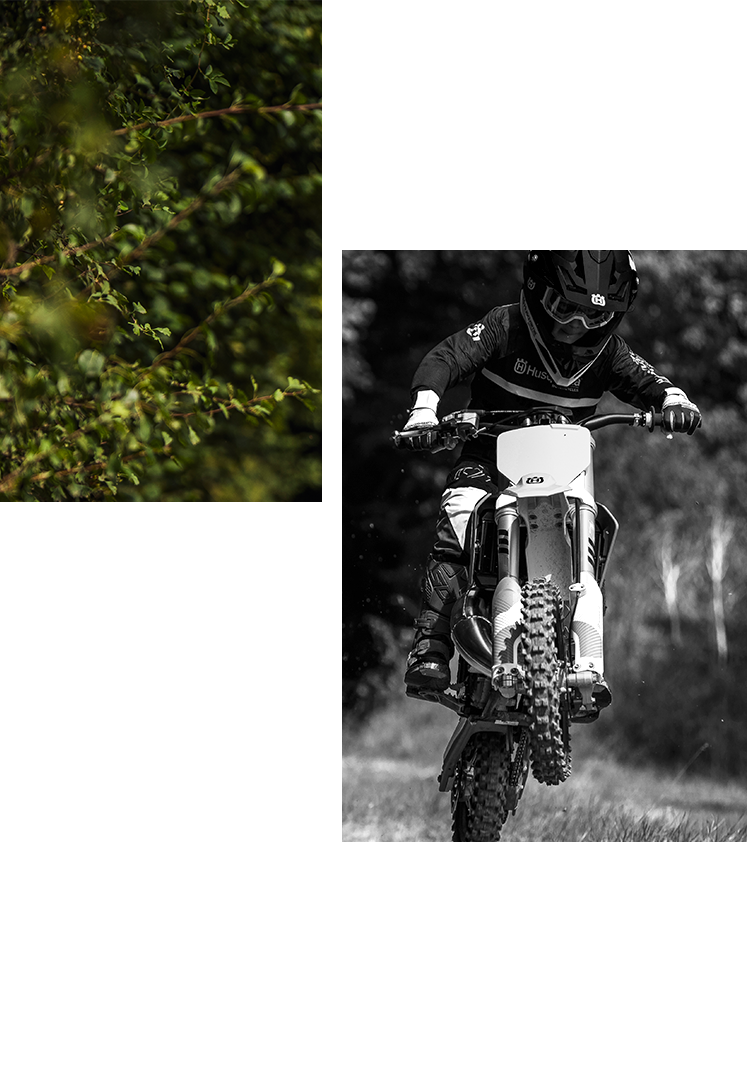

Having just won his second successive FIM SuperEnduro World Championship title, Husqvarna Factory Racing team star Billy Bolt has again validated the highly efficient technical package of his FE 350. His success further enhances the reputation of Husqvarna Motorcycles, underlining the status of the entire enduro line-up as the competition benchmark.