01. Faster and wiser

Engine

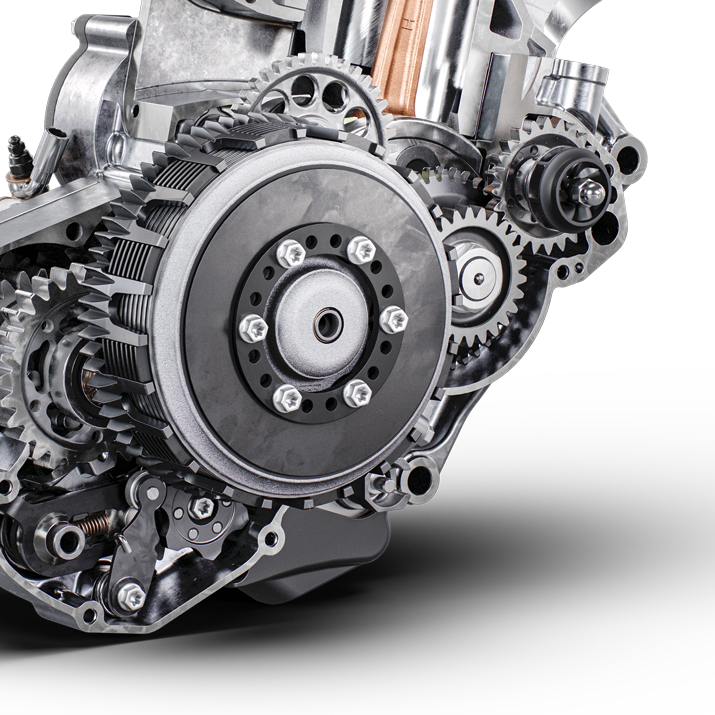

The fuel-injected, 300 cc engine offers the best combination of unrivalled peak power and usable torque. Lightweight in construction, the engine design centralises mass, which plays a vital role in the handling and agility of the new machine. An electronic exhaust control system tailors the power in every gear to ensure maximum performance on every part of the race track. The new TC 300 57hp engine is easy to maintain, with clear markings on the engine covers indicating where to check the gearbox oil level, as well as where to drain the coolant from.

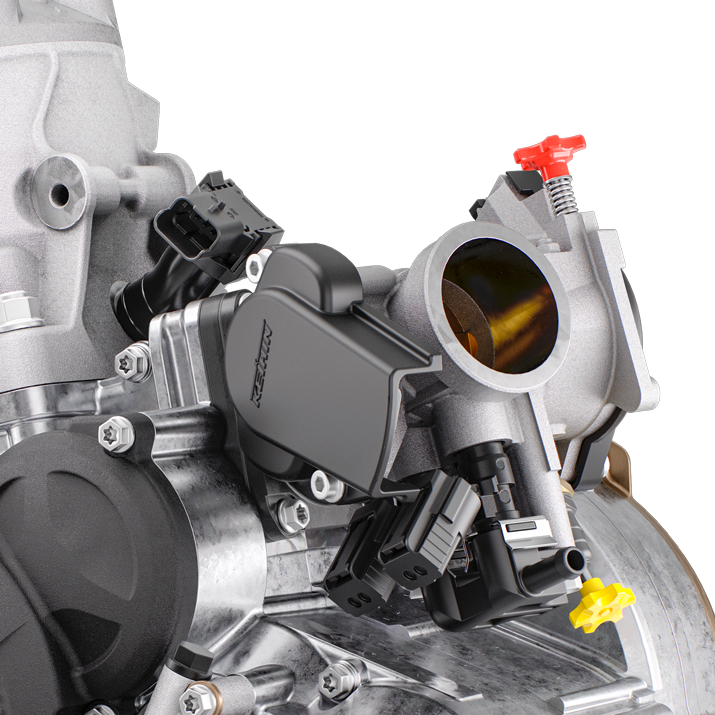

Cylinder

With Electronic Fuel Injection (EFI) as standard on the TC 300, the traditional powervalve is replaced with an electronic exhaust control system. This highly innovative technology manages the opening of the lateral exhaust ports before the main exhaust ports open to deliver strong, controllable power. The upper contour of the exhaust port features a machined finish for improved port timing and unrivalled performance.

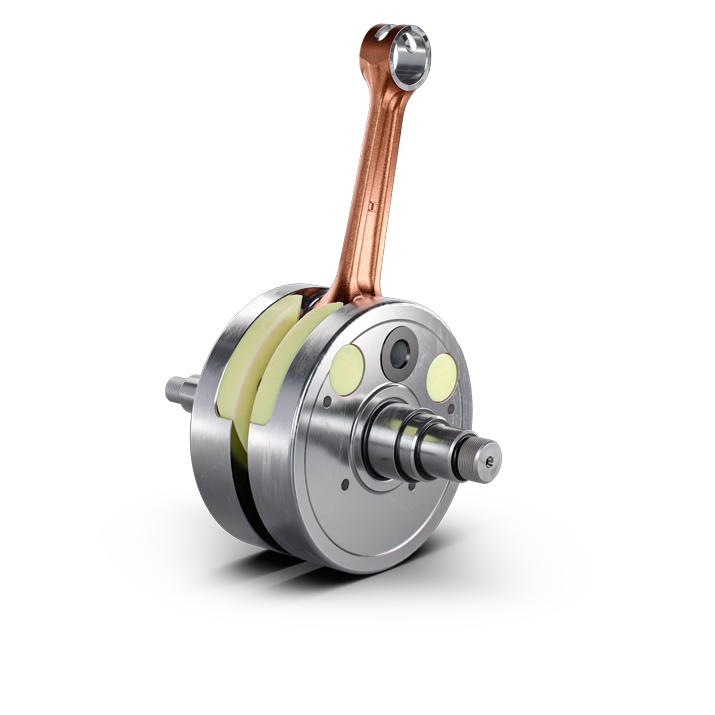

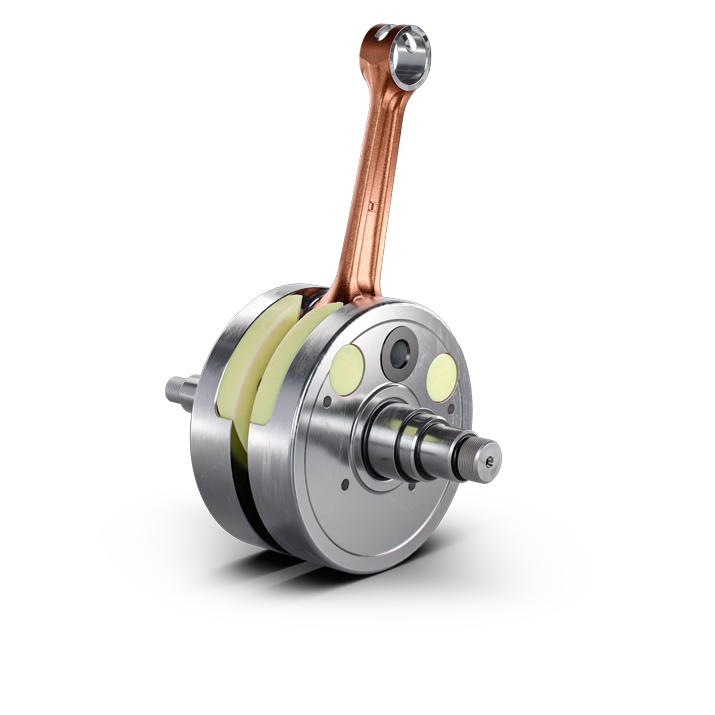

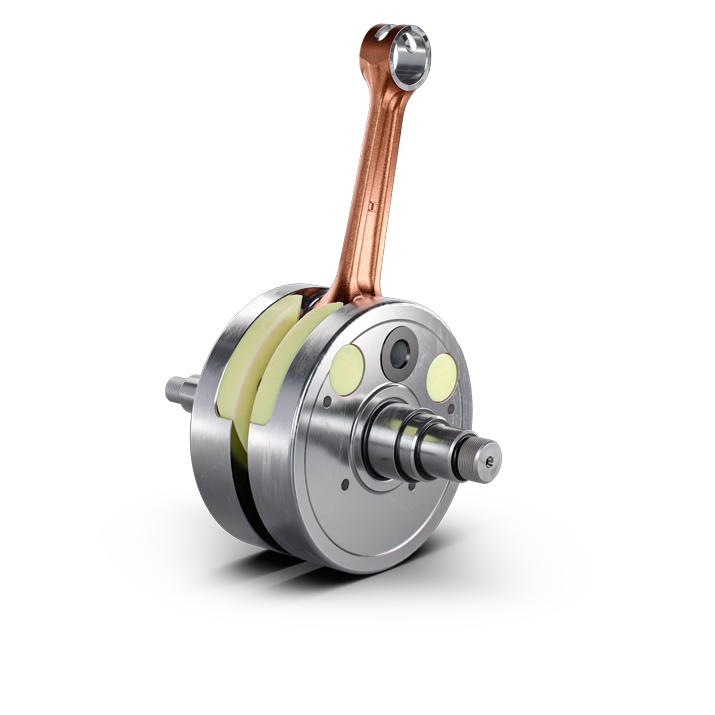

Crankshaft

The crankshaft is designed with weight reduction in mind to increase throttle response. The perfect balance of rotating masses is achieved by balancing the weights of the crankshaft flywheel, the rotor, and the counter balancer shaft.

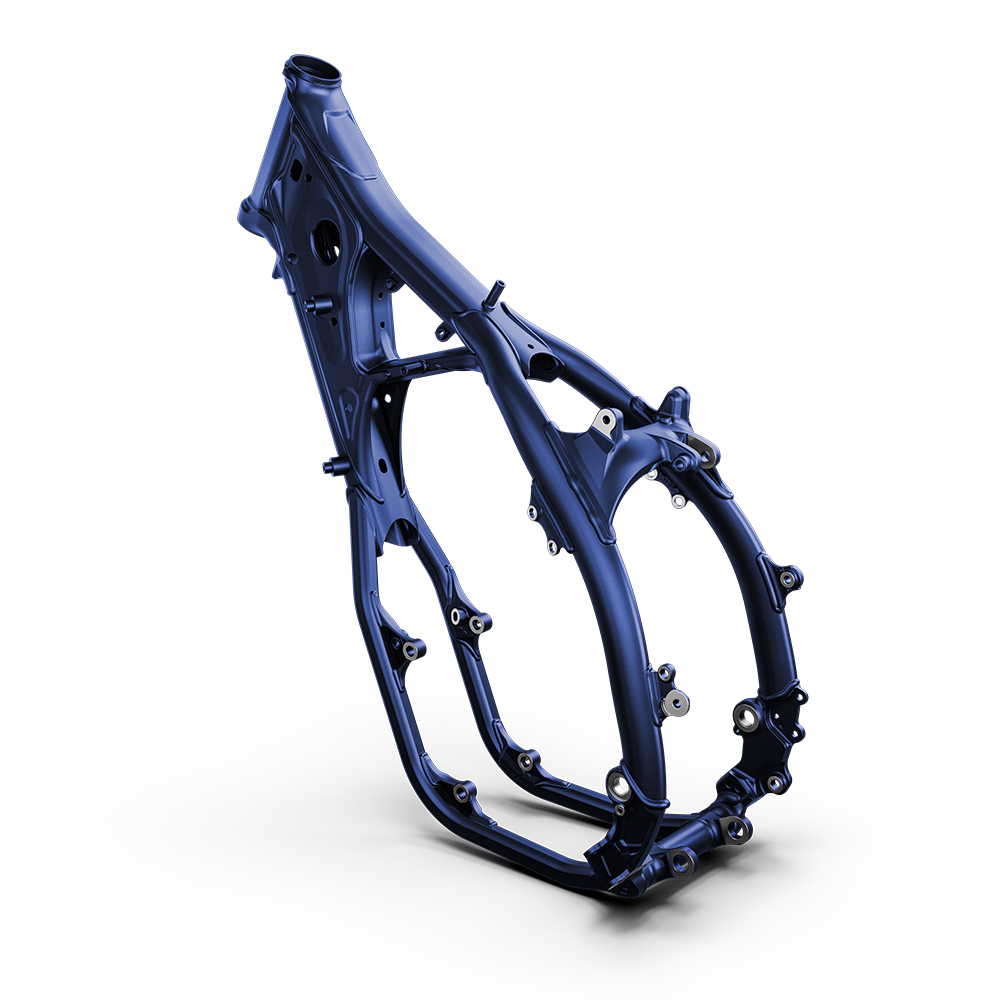

Crankcases

High-pressure die cast production processes allow for the crankcases to be manufactured with a thinner wall thickness to keep the overall weight to a minimum and to position the shaft arrangements perfectly for optimised mass centralisation. This clever design aids the overall balance and agility of the TC 300 while the symmetrical engine mounts contribute to the chassis' flex characteristics.

Counter balancer shaft

The TC 300 features an innovative laterally mounted counter balancer shaft. This shaft significantly reduces engine vibration, resulting in a smoother and more comfortable ride.

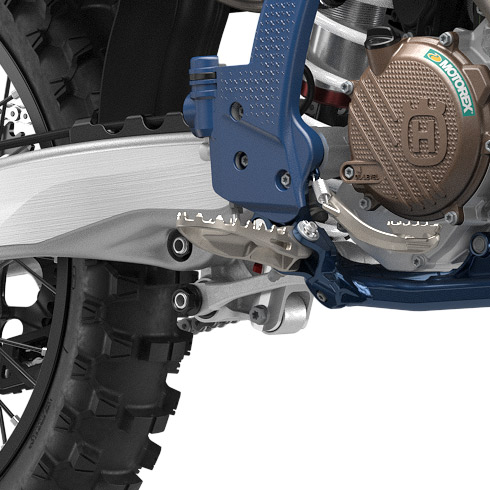

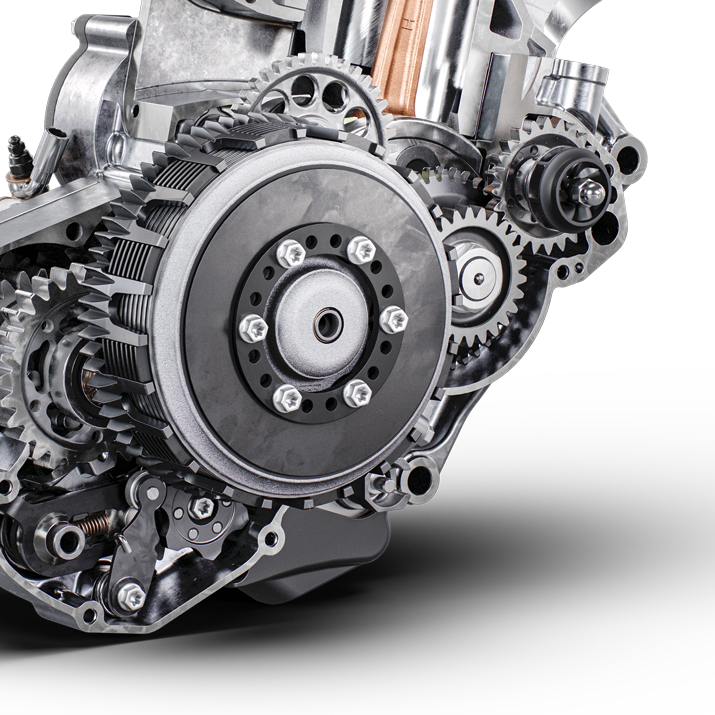

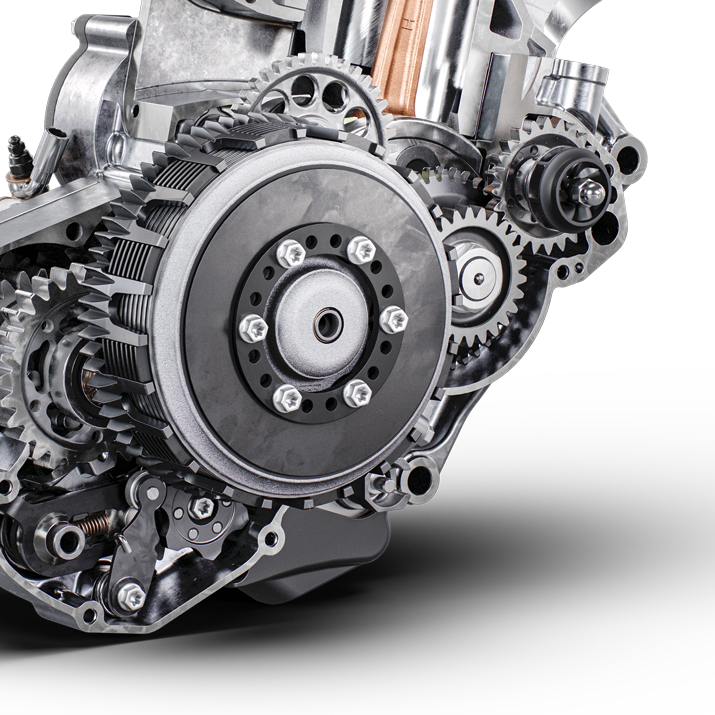

DDS clutch

The damped diaphragm steel (DDS) clutch fitted to the TC 300 is unique as a single diaphragm steel pressure plate is utilised instead of traditional coil springs. Housed inside a CNC machined steel basket, the overall clutch design contributes to the compact engine layout and features a damping system for improved traction and durability.

Gearbox

The TC 300 features a 5-speed gearbox manufactured exclusively by Pankl Racing Systems for the highest level of durability and ensures smooth and precise shifting. In addition, the gear lever tip design offers improved leverage and prevents dirt build-up, even in the toughest conditions.

Engine

Cylinder

Crankshaft

Crankcases

Counter balancer shaft

DDS clutch

Gearbox