01. Faster and wiser

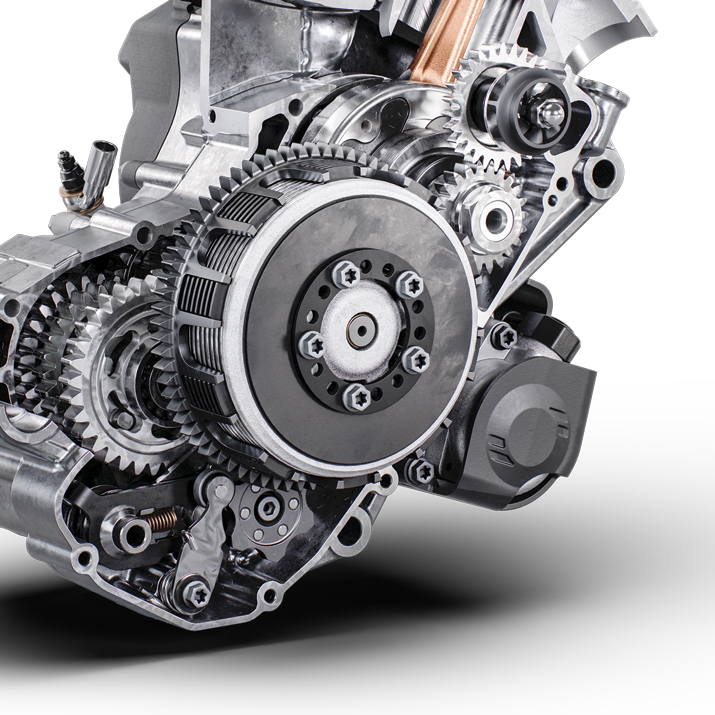

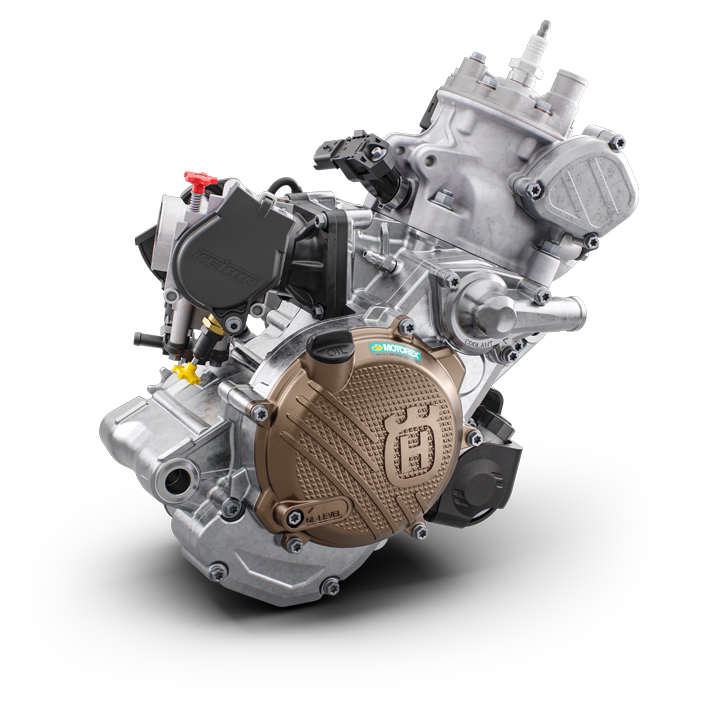

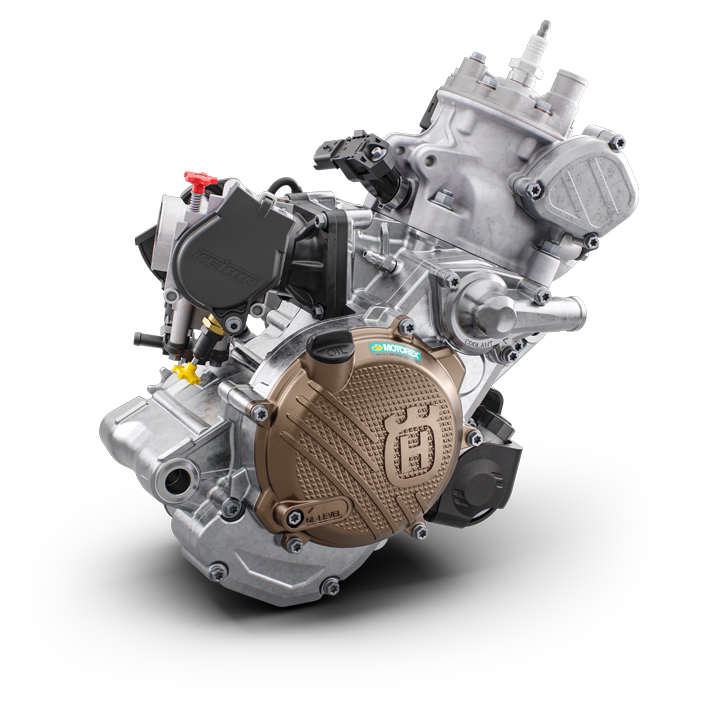

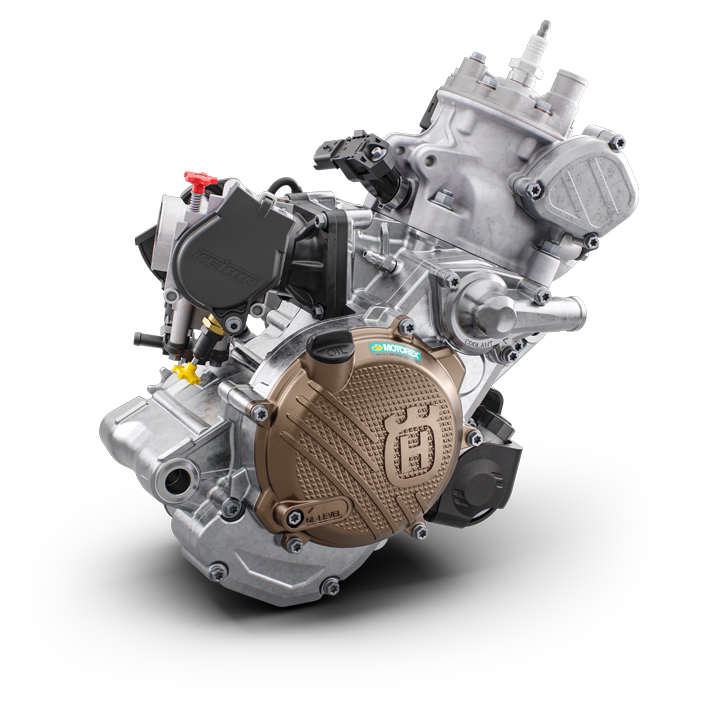

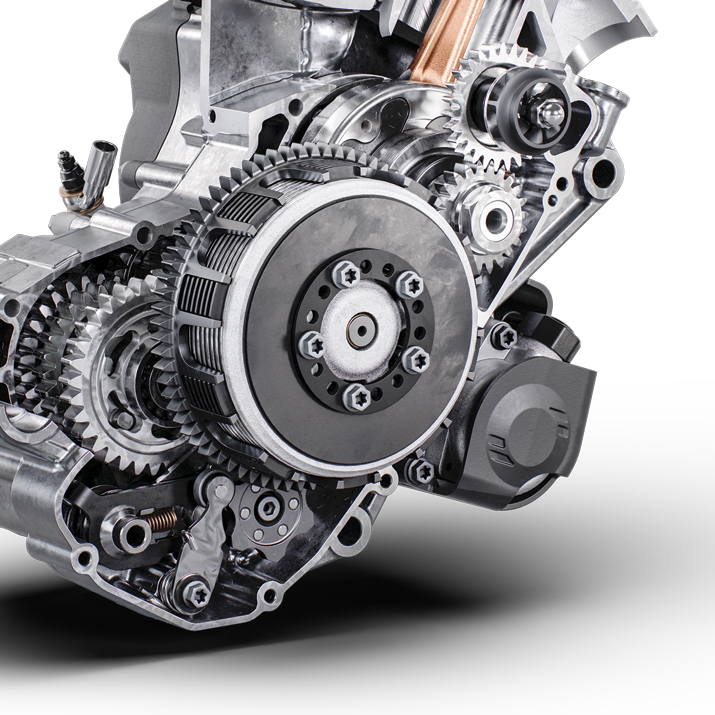

Engine

The TC 125 engine sets the standard for performance in the highly competitive 125 cc class and weighs in at just 17.9 kg. The lightweight engine is manufactured using the latest engineering techniques to produce more torque while retaining its high-revving 2-stroke character. With the rotating mass inside the engine centralised, the TC 125 offers light and agile handling to the benefit of both beginners and professional racers.

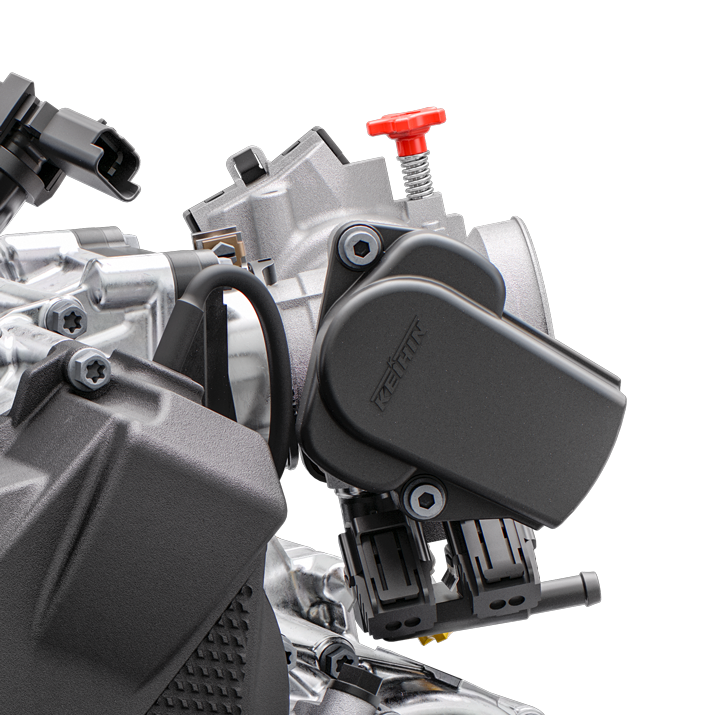

Cylinder

The cylinder features a 54 mm bore and an innovative electronic exhaust control system. Using an actuator, the lateral exhaust port and main exhaust port open simultaneously for maximum power delivery.

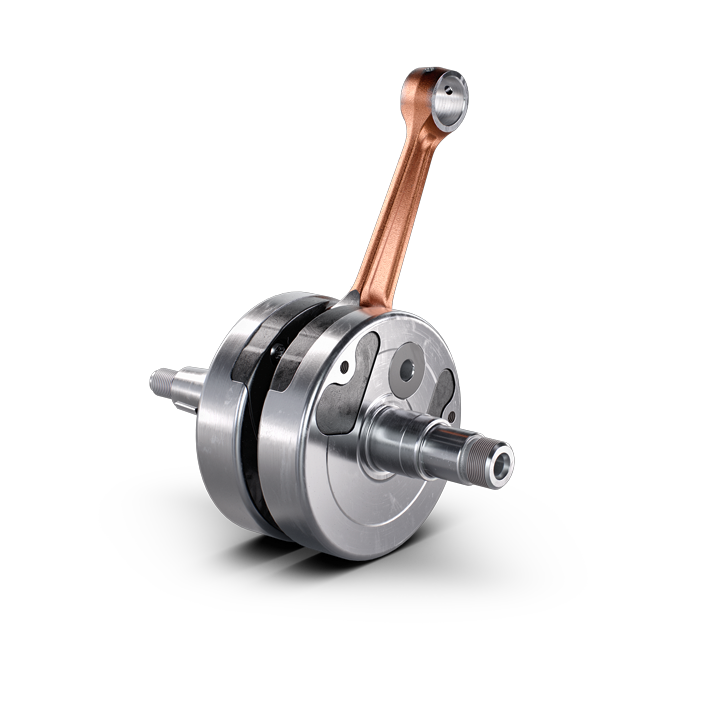

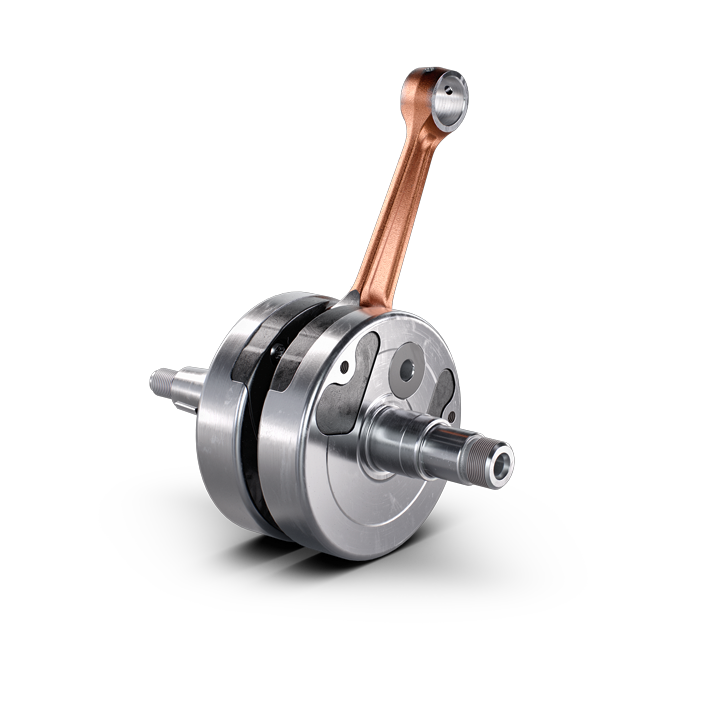

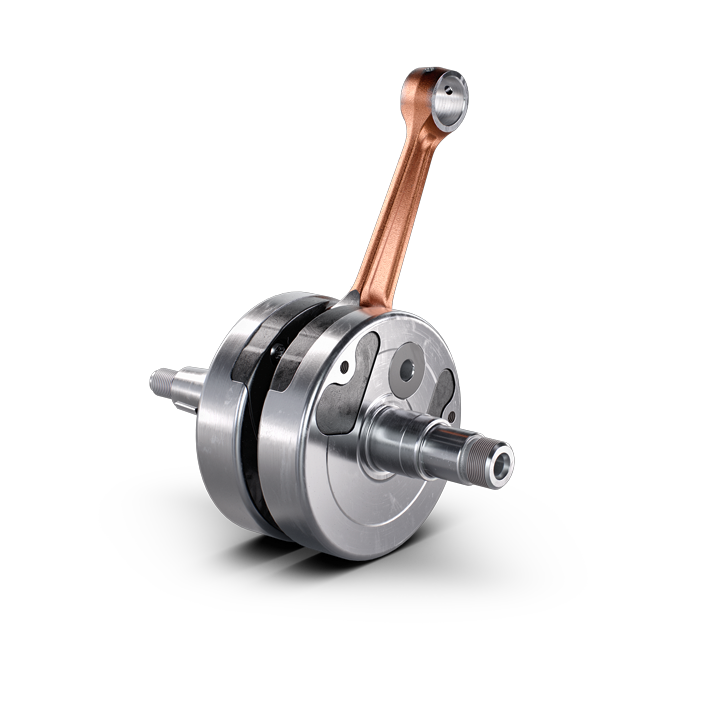

Crankshaft

The lightweight crankshaft improves throttle response and reduces vibration to a minimum. The component is precisely positioned to ensure rotational mass has very little effect on the overall handling of the motorcycle.

Crankcases

High-pressure die cast production processes allow for the crankcases to be manufactured with a thinner wall thickness to keep the overall weight to a minimum and optimise mass centralisation. Symmetrical engine mounts aid handling by contributing to the flex characteristics of the chassis. Internally all engine components are positioned to achieve an ideal centre of gravity.

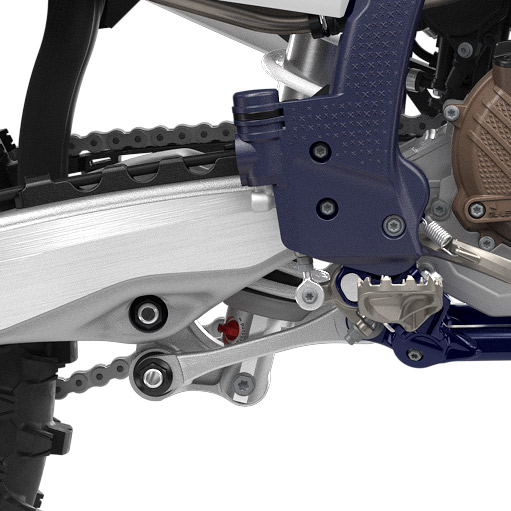

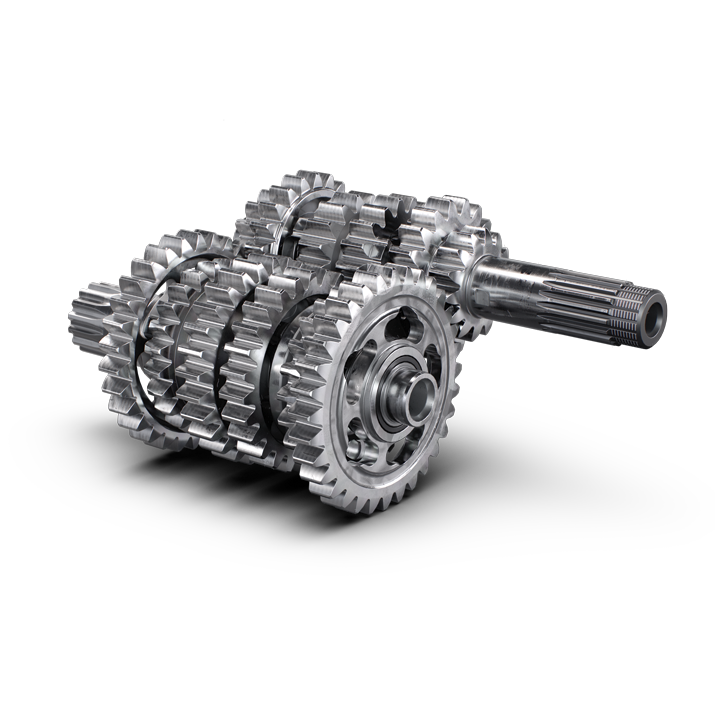

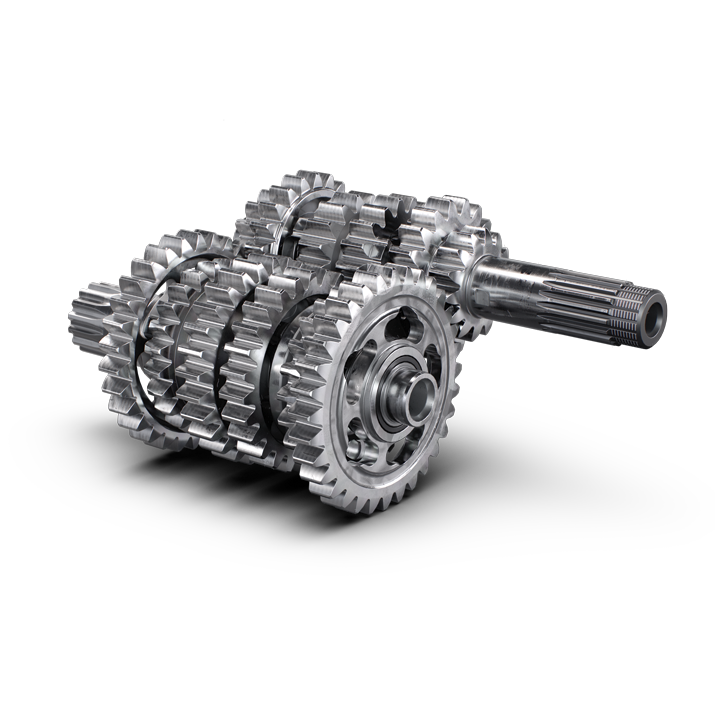

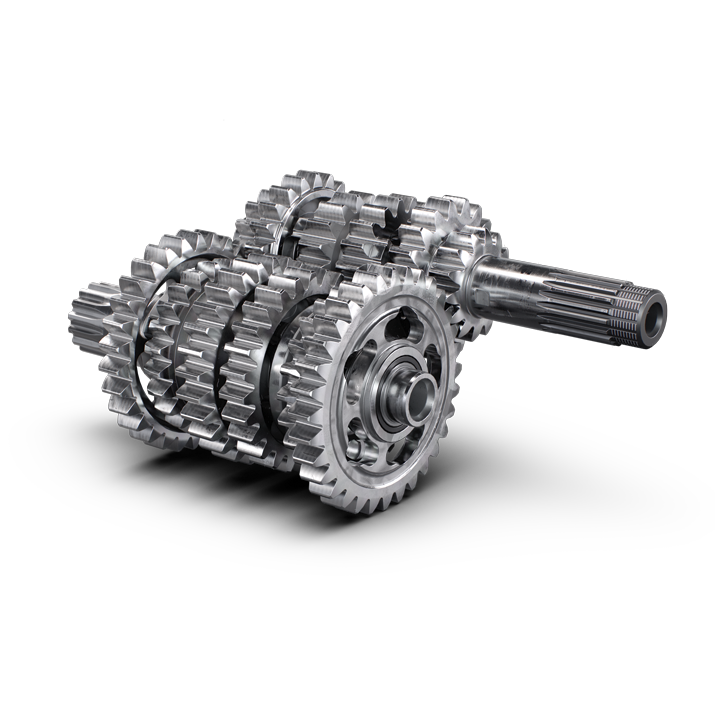

Gearbox

The 6-speed gearbox is manufactured exclusively by Pankl Racing Systems and ensures the highest level of durability and reliability. The shift drum and shift fork improves overall leverage for significantly smoother and more precise shifting. A special gear lever tip design prevents dirt build-up for positive gear changes in all conditions.

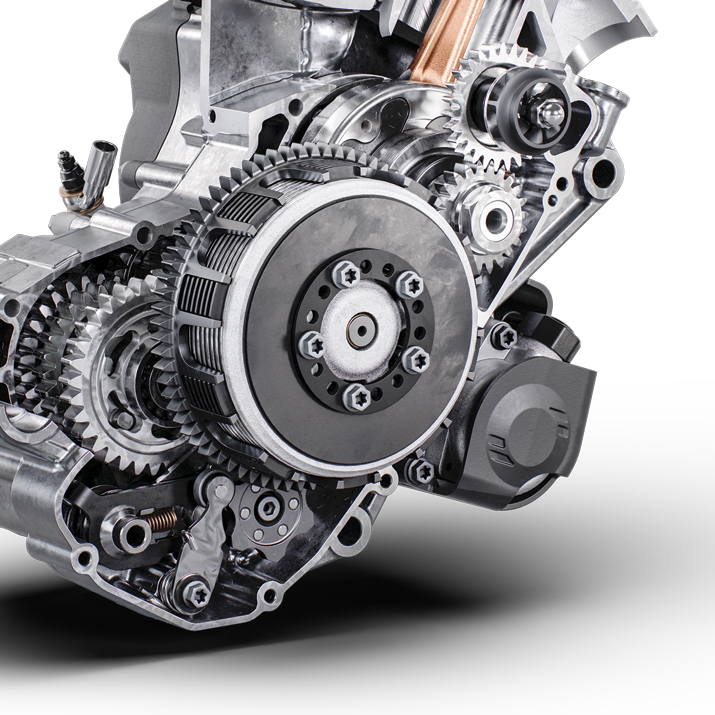

DS Clutch

The diaphragm steel (DS) clutch fitted to the TC 125 features a unique design where a single diaphragm steel pressure plate is used instead of traditional coil springs. Housed inside a CNC machined steel basket, the overall clutch design is highly durable and contributes to the compact layout of the engine.

Engine

Cylinder

Crankshaft

Crankcases

Gearbox

DS Clutch