Engine

The 300cc 2-stroke engine is the benchmark for unrivalled power in a lightweight construction. The engine features precisely positioned shaft arrangements for optimal mass centralisation, a counter balancer shaft reducing vibration, a twin-valve controlled power valve, and 6-speed enduro gearbox.

The TE 300 Heritage features an advanced Electronic Fuel Injection system. This comprises a set of fuel injectors positioned at the transfer ports which deliver the ideal amount of fuel into the engine for every condition. This not only reduces fuel consumption and emissions, but also delivers a clean and smoother power delivery.

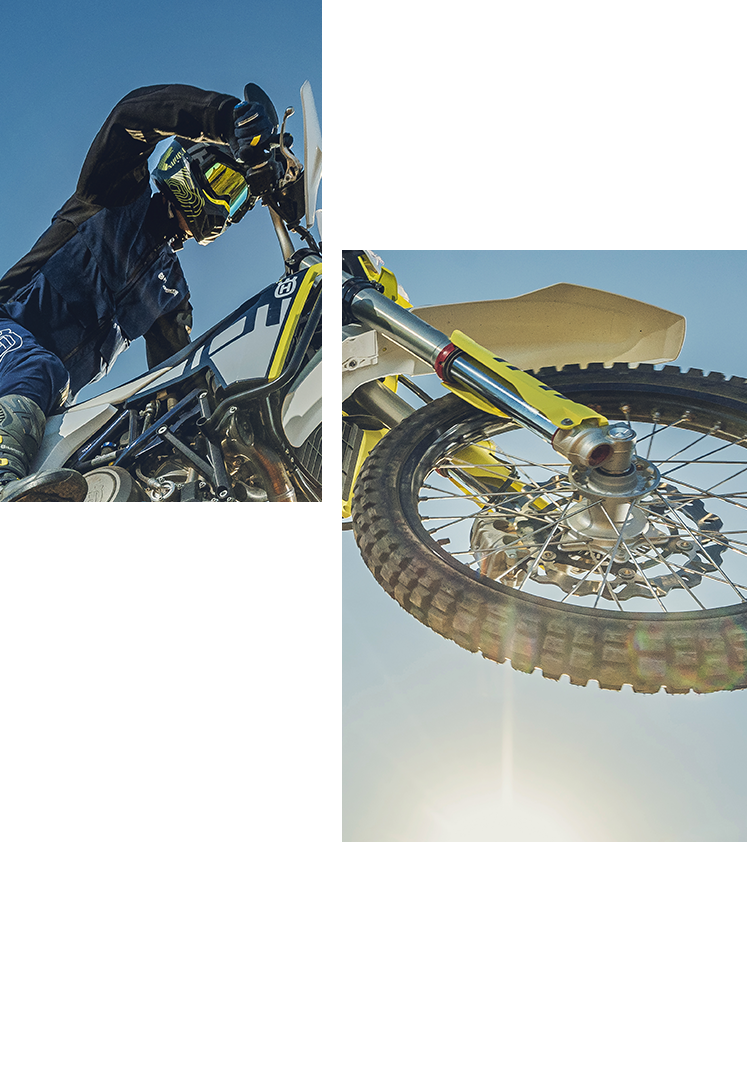

Cylinder

The 72 mm bore cylinder features a twin valve-controlled power valve system which delivers smooth and controlled power throughout the RPM range. Optimal exhaust port timing is achieved with the combination of a state-of-the-art, adjustable power valve drive and machined exhaust port window.

Additionally, the cylinder features two inlet positions located on the transfer ports at the rear of the cylinder where a pair of fuel injectors are mounted. The injectors deliver the fuel downwards into the transfer port which guarantees excellent atomisation with the air travelling upward to the combustion chamber. This ensures a more efficient combustion resulting in reduced fuel consumption and emissions.

- Dual fuel injectors → excellent atomisation, reduced fuel consumption

Piston

The lightweight piston is perfectly matched to the cylinder and transmits minimal oscillating mass ensuring high levels of performance and reliability.

- Piston → high performance and reliability

Engine casings

The TE 300 Heritage engine is designed to improve mass centralisation. As a result, the lightweight, die-cast engine casings are developed to accommodate a shaft arrangement aimed at centralising oscillating mass and improving rideability. Additionally, the counter balancer shaft is integrated in a very compact manner and little effect on the overall design.

Additionally, the water pump casing is designed for effective cooling by optimising the flow of coolant.

- Die cast engine casings → mass centralisation, optimal handling

- Water pump casing → optimal flow of coolant for effective cooling

Counter balancer shaft

The engine houses a laterally mounted counter balancer shaft. The balancer significantly reduces vibration resulting in a smoother and more comfortable ride.

- Counter balancer shaft → significantly reduced vibration