Airbox and tool-less air filter access

The CFD optimised airbox is designed with precisely positioned inlet ducts to prevent air deformation and ensure maximum airflow and filter protection. The air filter is easily accessed, without tools, by removing the left side panel. Easy maintenance is guaranteed by the Twin Air filter element and filter cage design, featuring a simple, fail-proof mounting system for safe and accurate filter installation.

- CFD optimised airbox → exceptional air flow and maximised filter protection

- Intuitive filter mounting system → safe and accurate protection against dirt

- Tool-less filter access → quick and easy maintenance

- High-flow airbox cover in the by-pack → added customisability of the engine response

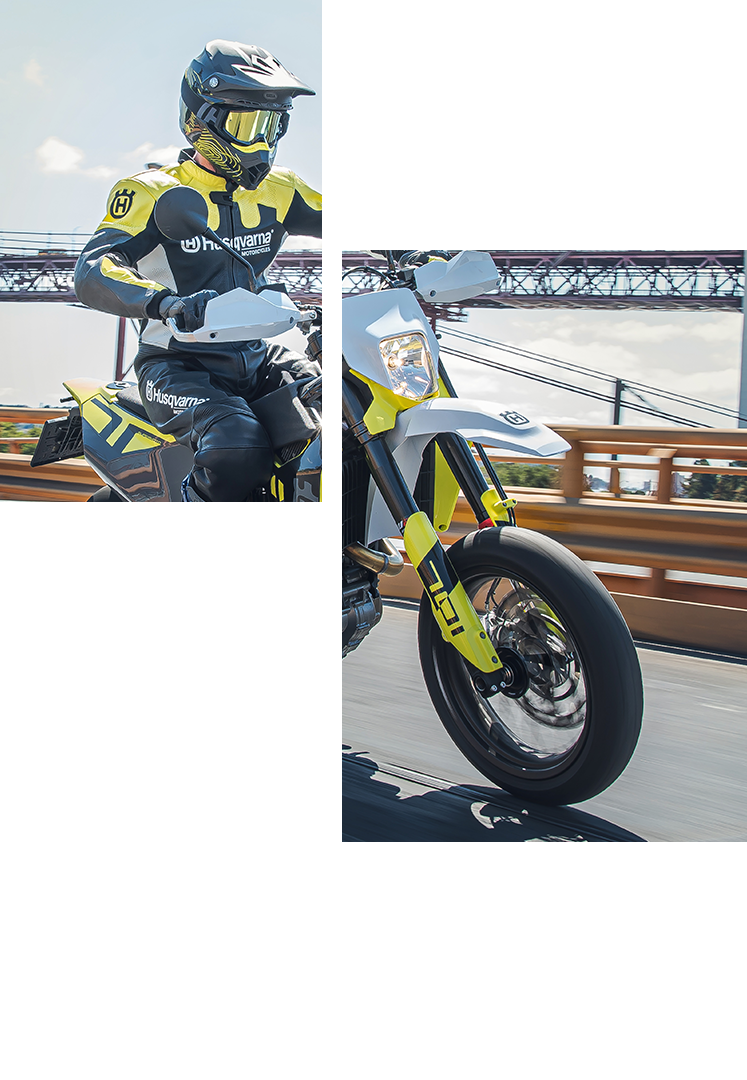

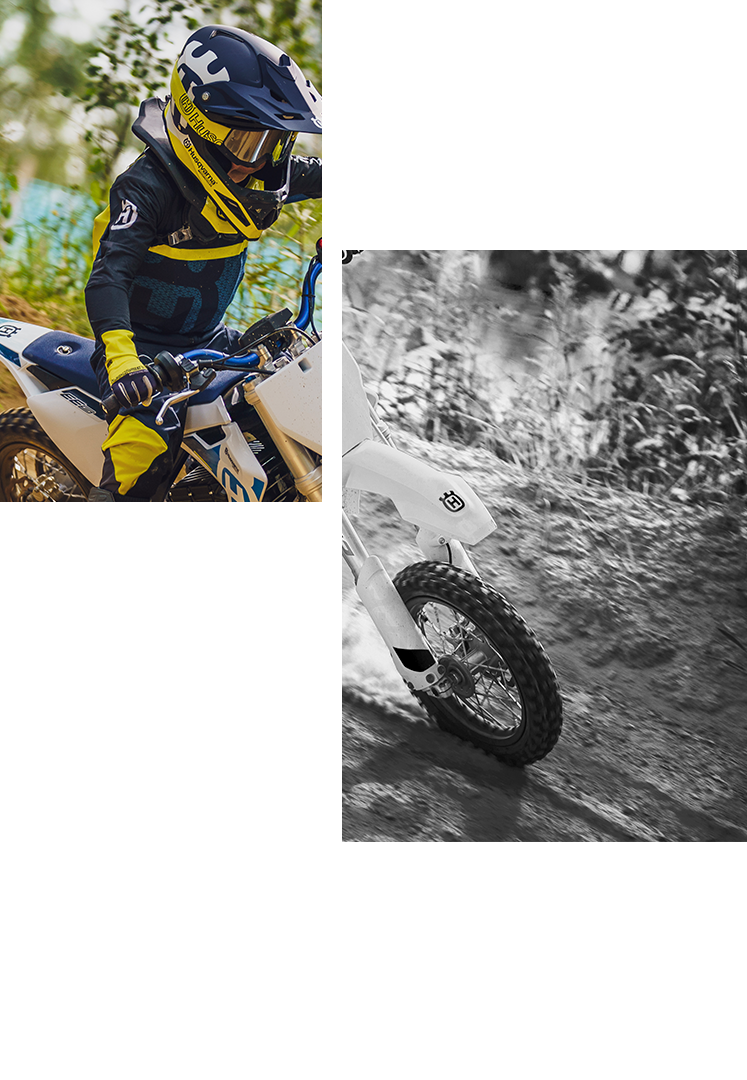

Wheels and tyres

Black 16.5”/17” Alpina spoked wheels on the front and rear respectively, are lightweight and strong. They are complemented by Metzeler Racetec SM K1 125/75 R420 and 165/55 R420 slick tyres for maximum grip, traction, and agility.

- Lightweight but strong and reliable wheel construction → minimum unsprung weight

- Innovative mixing process and high ultra-fine silica compound delivering quick warm-up times

- K1 compound for a big usage window (smooth to severe asphalt and hot to cold temperatures) allows usage without tyre warmers

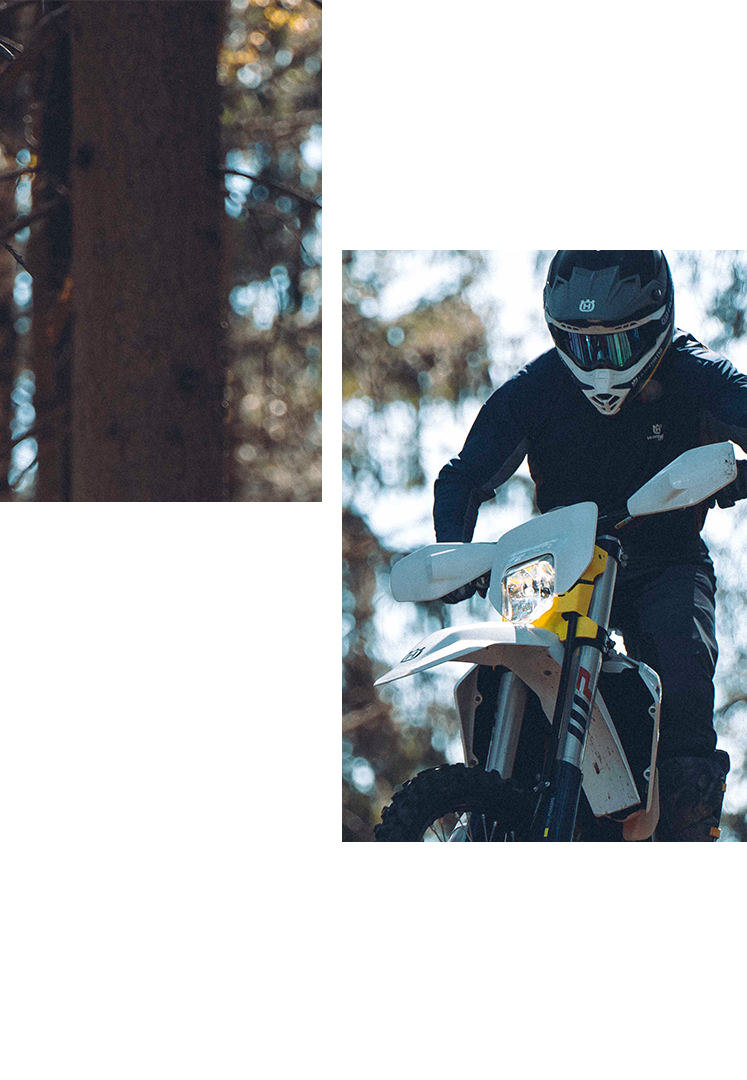

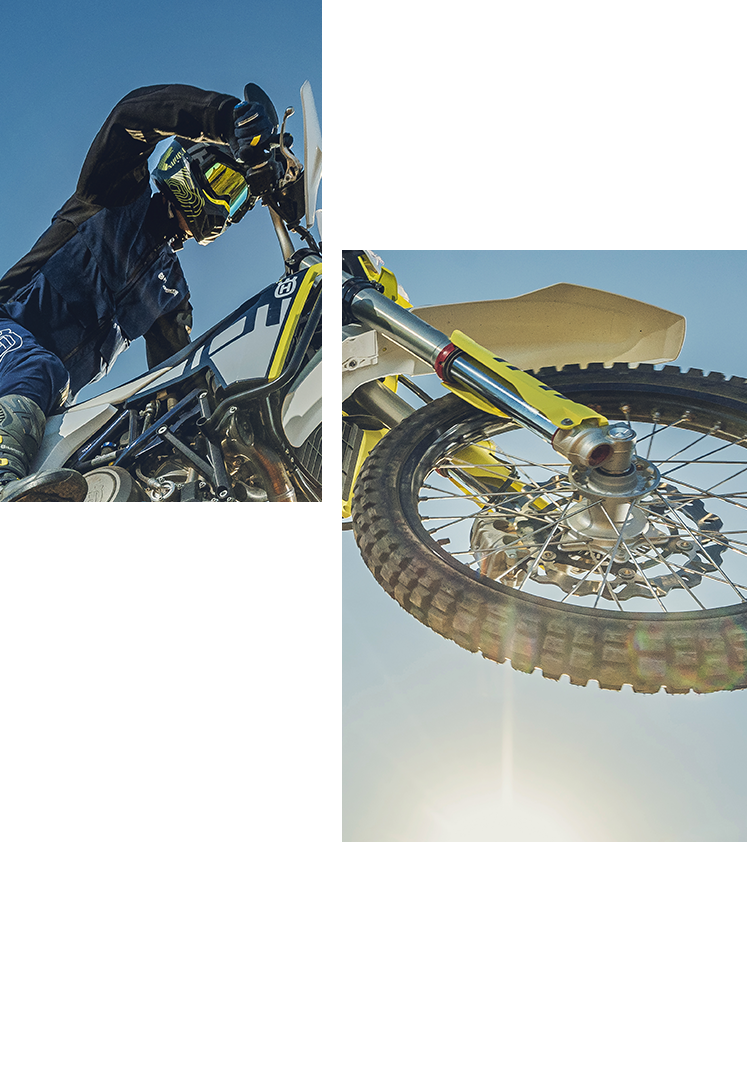

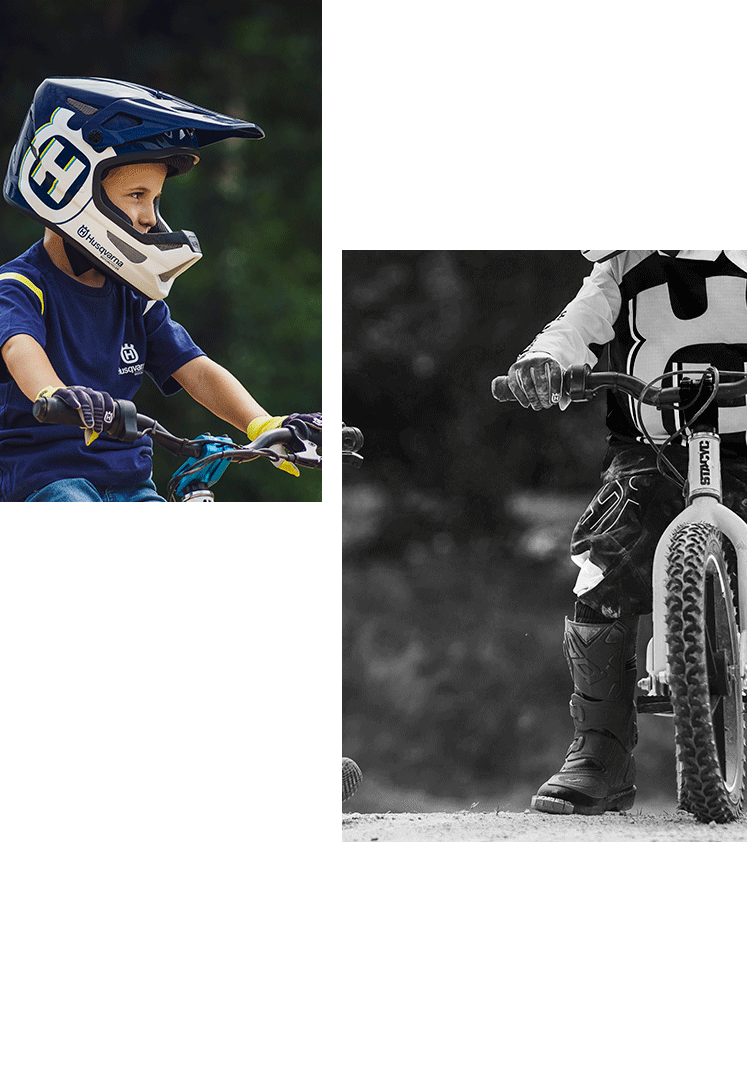

Bodywork

The FS 450 features bodywork that clearly showcases Husqvarna Motorcycles progressive approach to offroad motorcycles while striking grey and yellow graphics stylishly adorn the Swedish-inspired design.

An optimised rider triangle for better knee contact, especially when riding in the standing position, inspires confidence for riders of every ability and enables them to perform at the highest level for extended periods of time. The slim contact surfaces on the bodywork allow the rider to move the FS 450 around more easily on track and improve the overall handling and agility of the motorcycle.

The flat seat profile, combined with a new high grip seat cover, deliver superior comfort and control in all conditions. A recessed pocket under the seat, just above the airbox, allows gripping and lifting of the bike.

- New grey and yellow graphics → striking yet simple design

- Optimised rider triangle for exceptional knee contact, especially when riding in the standing position

- Additional contact surface → allows for improved gripping and easier movement of the bike

- Recessed grip pockets → allowing better grip to lift the bike

- Seat → flat seat profile and new high-grip seat cover for exceptional comfort and control in all conditions