Introduction

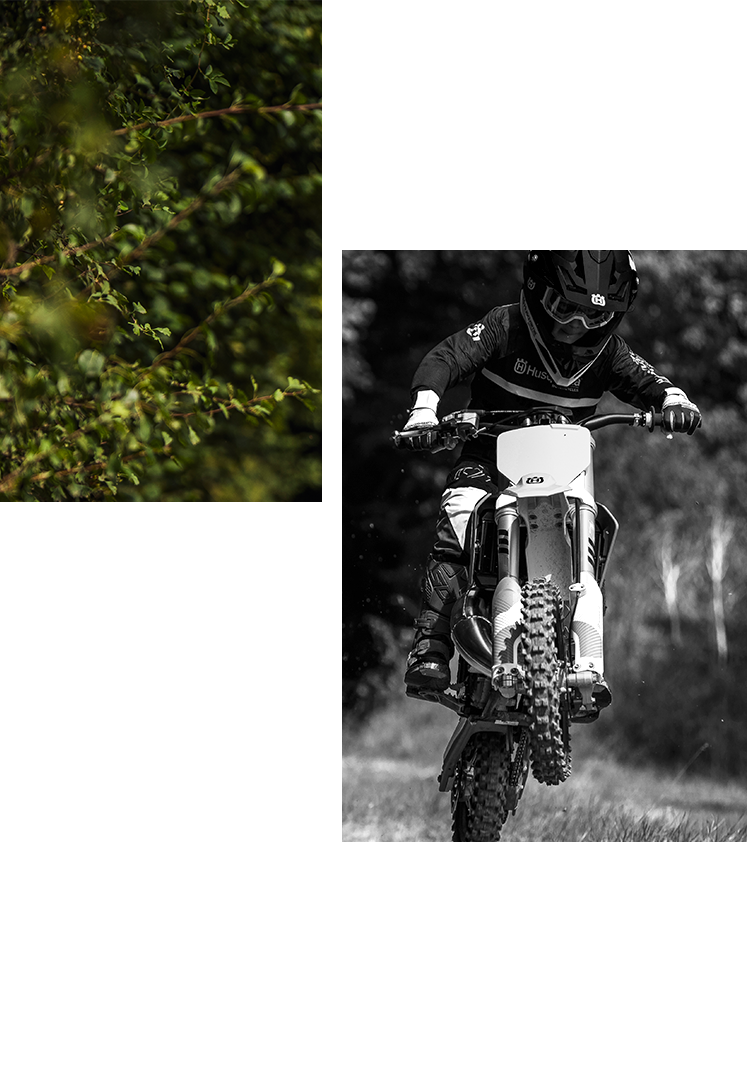

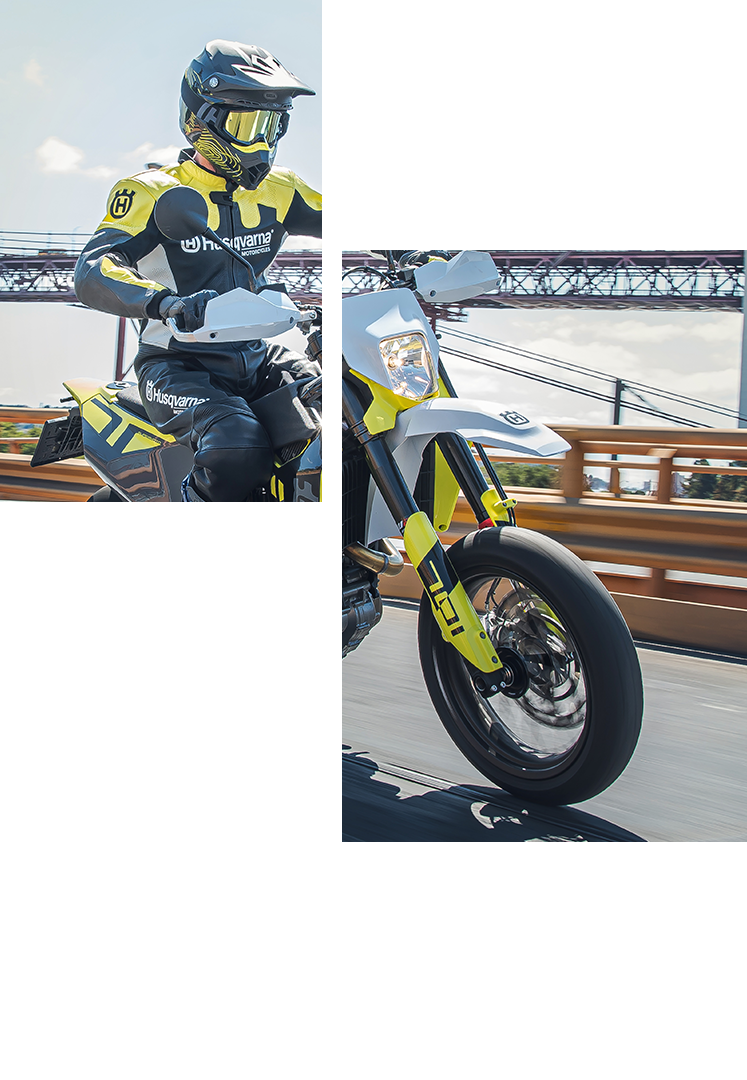

Built upon the proven technical platforms of the 2023 range, the Heritage motocross models are modern, competition-focused, and further enhanced with a Swedish-inspired, vintage-style livery together with black EXCEL rims. The distinctive new look, influenced by the brand’s successful racing heritage, undoubtedly creates an exclusive and understated appearance. Finished with a matching blue seat cover, the Heritage models pay homage to the strong Swedish roots of Husqvarna Motorcycles.

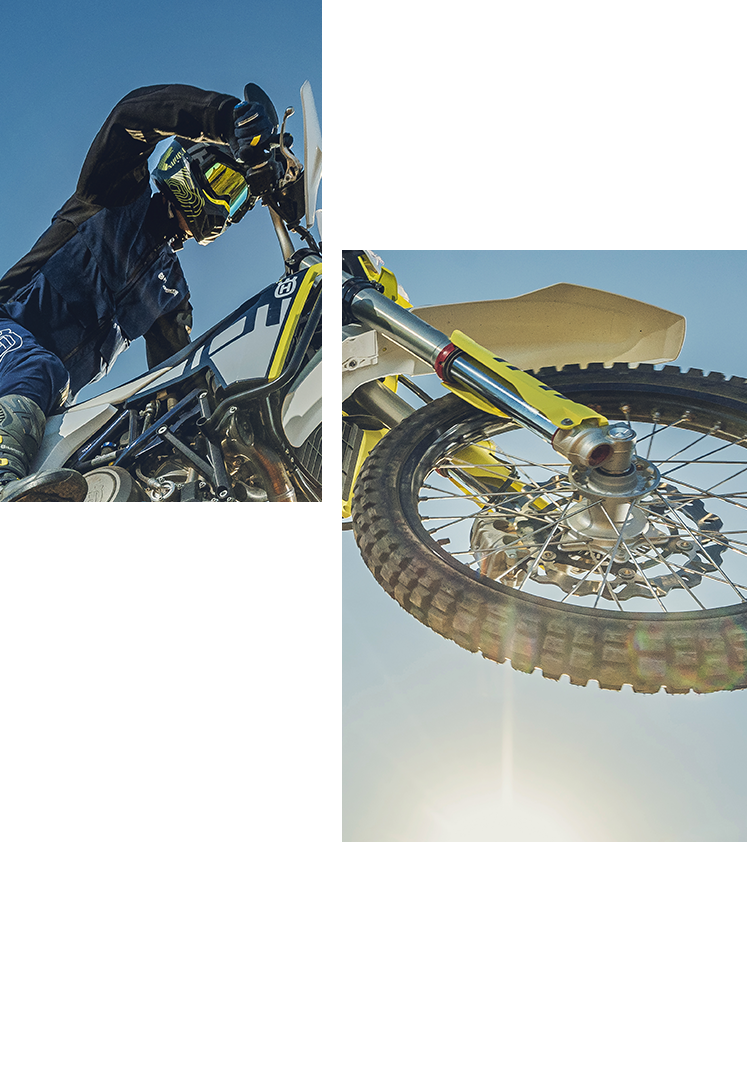

Across each of the five models, new premium suspension, frames, swingarms, and bodywork highlight the chassis revisions, further improving overall handling for enhanced on track performance. Expertly assembled with high quality components and the latest innovations, the TC and FC Heritage models continue to set the standard for premium motocross machinery.

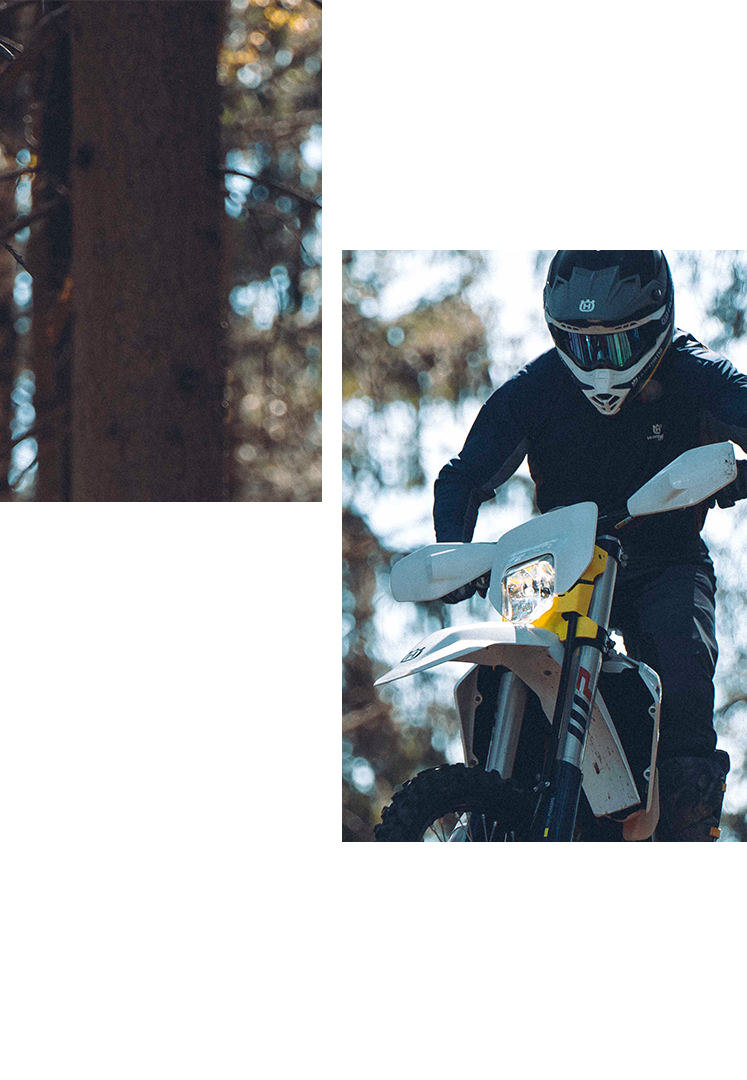

Strengthening their positions as the leading 2-strokes on the market for 2023, the TC 125 Heritage and TC 250 Heritage are now equipped with Electronic Fuel Injection (EFI) and E-Start as standard. These significant advancements underline the continued development of these popular machines and set the benchmark within the highly competitive 2-stroke sector.

The 2023 FC 250 Heritage and FC 350 Heritage are powered by new engines designed to be faster, lighter, and enhance overall handling. Continuing to utilise the latest technology and rider aids, these 4-stroke models remain at the pinnacle of motocross machinery alongside the FC 450 Heritage, which features a repositioned engine to improve mass centralisation and a redesigned cylinder head for optimal torque and performance.