Handlebars and grips

The tapered handlebar (black, unbranded) is made of high-quality aluminium alloy ensuring stability, vibration damping, and safety. Its diameter reduces in size from the central, 28 mm clamping area to 22 mm in the bends through to the bar ends which measure 18.1 mm.

The complete bend has been revised with the specific needs of young riders in mind (more like a full-size handlebar now with a less steep bend). Riding will now feel and look much more modern with a completely different body position on the machine.

Thin diameter ODI grips are a major benefit to young riders as they will enjoy a better grasp while riding which increases their control and drastically reduces fatigue. The bar pad on the handlebar protects the rider in the event of a heavy impact.

Alternative grips, levers, and handlebars are available as Technical Accessories and allow riders to further refine the ergonomics of the TC 50.

Brakes

Equipped with the same level of technology offered on Husqvarna Motorcycles’ full-size motocross model range, the TC 50 features hydraulically operated brake calipers and waved, state-of-the-art front and rear brake discs. The system ensures an advanced braking feeling and stopping power in all conditions.

For 2024, the overall functionality of the brake system has been improved which is particularly noticeable when riding in extreme conditions (wet/rainy weather, muddy, dusty tracks). Additionally, the durability of the system has been improved which leads to longer lasting performance.

The brake hose routing to the rear brake calliper no longer interferes with the rear shock reservoir which maintains performance and increases durability. A new, forged rear brake lever features the same tip as found on the full-size models which offers greater grip for improved control.

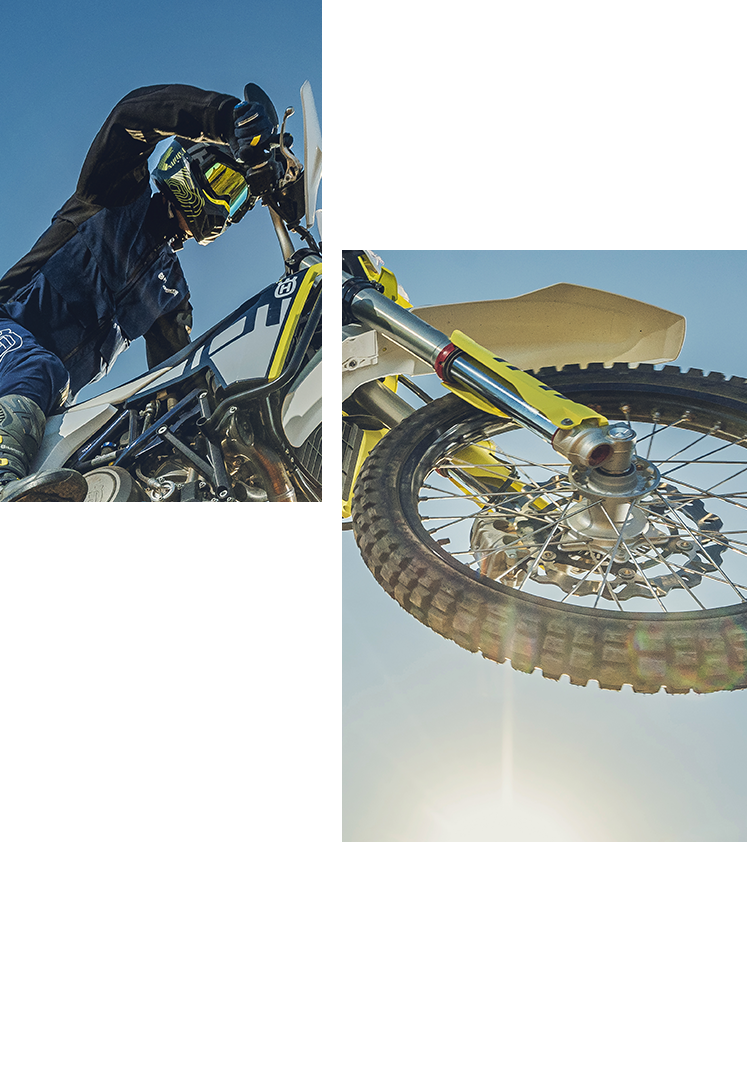

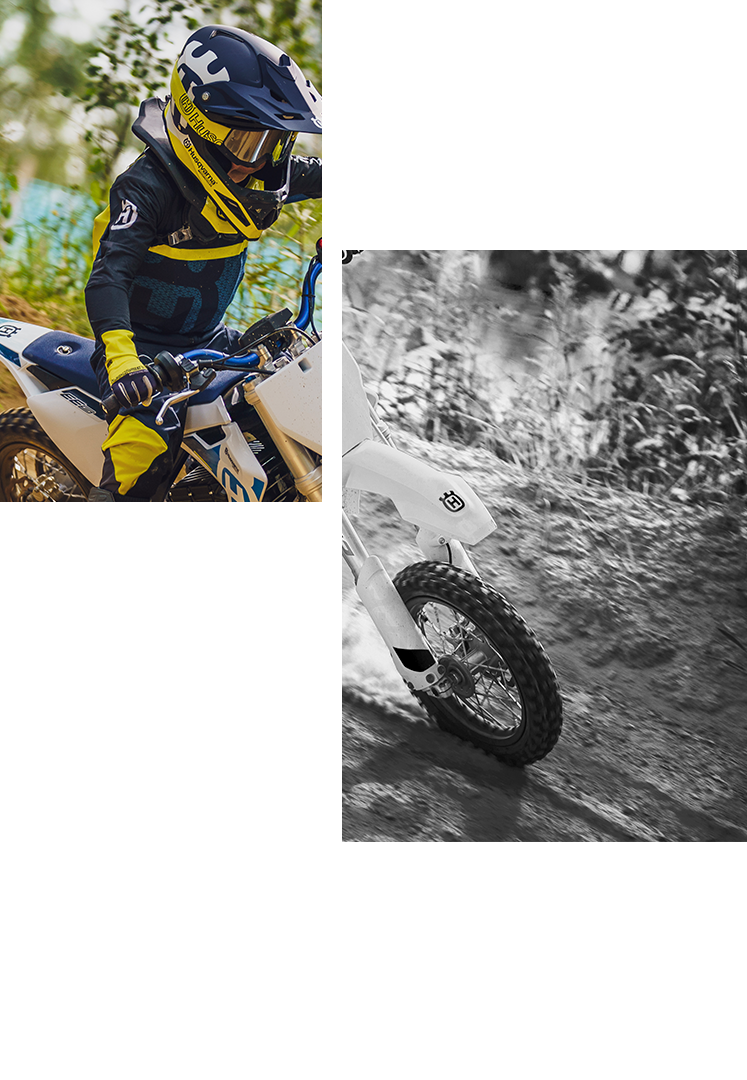

Wheels and tyres

Mirroring the full-size motocross range, the TC 50 uses lightweight, black anodised, aluminium rims. Together with the redesigned front and rear hubs, a high level of strength and reliability is assured. MAXXIS MX-ST tyres deliver outstanding performance on a variety of terrain with the pattern and rubber compound combining to offer exceptional straight-line stability and excellent traction.

- New MAXXIS MAXXCROSS MX-ST tyres - exceptional straight-line stability and excellent traction

- Lightweight, black anodised, aluminium rims with redesigned hubs (front/rear) à higher level of strength and reliability

Radiator

Featuring state-of-the-art technology, the TC 50 uses a liquid cooling system to cool the cylinder as well as the crank cases. The TC 50 now uses one large radiator with a larger capacity instead of two smaller separate ones.

The radiator louvres prevent damage from roost and channel air through the cooling fins efficiently to ensure superior cooling in all conditions. Together with a simplified routing of the radiator hoses, the running temperature of the TC 50 remains constant, even in slow speed, heavy conditions.

A cleverly designed radiator protector (left and right side) works as radiator holder, vibration dampener, and crash protector. The overflow hose is also integrated into the radiator protector.

The bodywork surrounding the fuel tank and the radiator protector connects with simple but efficient snap locks.

Air box and filter

The new airbox concept is produced by using a new technology - mirror welding. The base material of the air box is polyamide instead of the rubber found on the old generation.

The air filter mounting system now features snap locks for easy and intuitive mounting. The filter itself is provided by Twin Air and has a much bigger surface area, allowing more air into the intake which boosts power. It also features “Poka-Yoke” design for failproof mounting.

The air filter is placed under the seat and is accessible without using tools by removing the seat (quick release on seat).

Tank

The fuel tank capacity remains largely unchanged despite it being redesigned to work together with the new frame and bodywork.

Hourmeter

The hour meter now is mounted in the same position as found on the full-size models behind front number plate for easier reading and a lower risk of dirt and/or water intrusion.

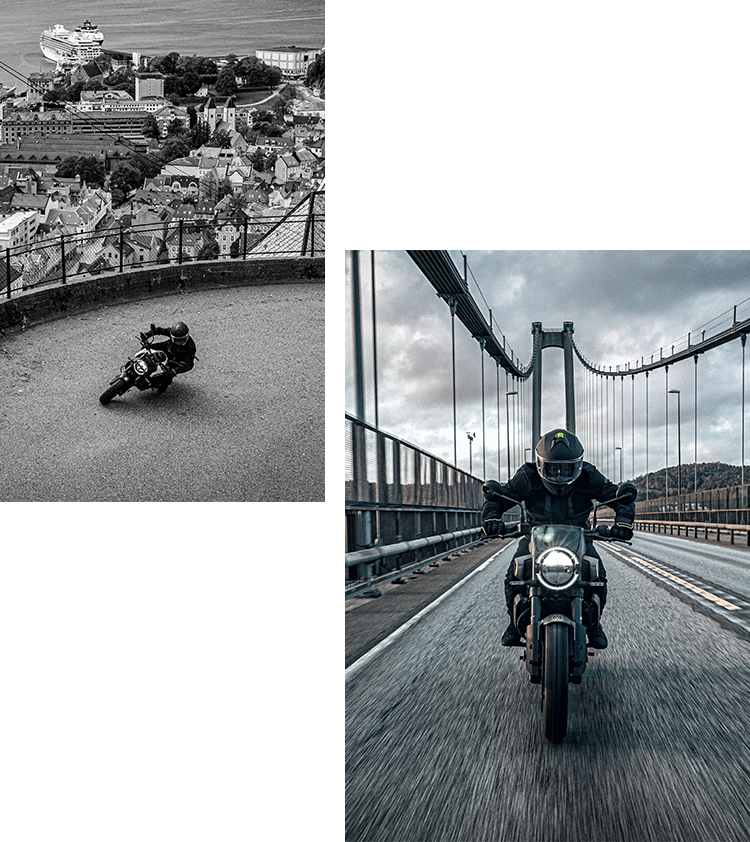

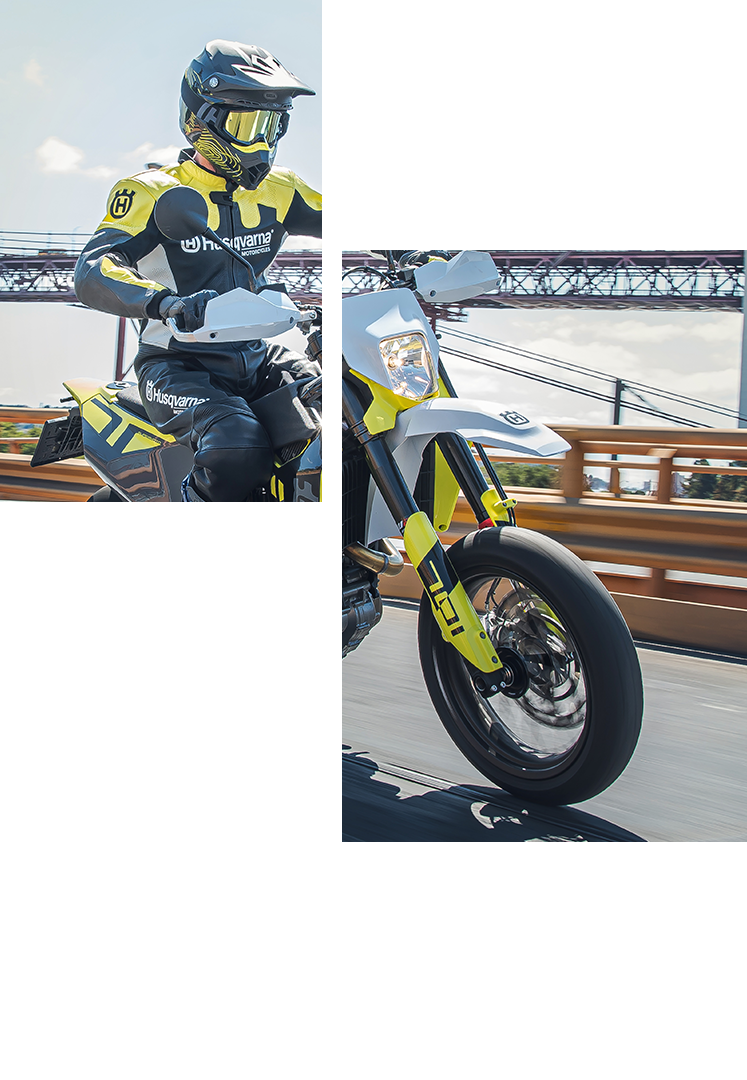

Bodywork

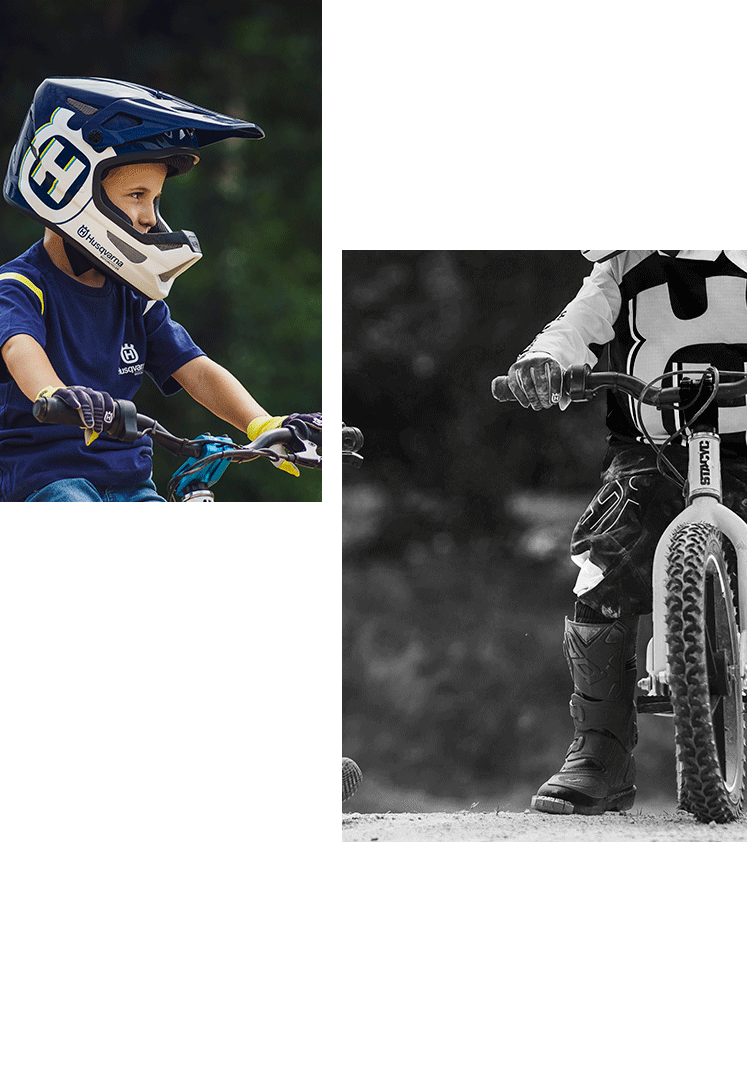

The all-new bodywork of the TC 50 is the perfect example of Husqvarna Motorcycles’ commitment to minicycles. A carefully balanced, scaled down design of our full-size TC bodywork finds its way onto the TC 50. This not only gives the bike the ultimate look, but it also gives young riders the ultimate feel.

The front number plate features an integrated lower triple clamp protector to prevent damage from roost. The tank spoiler features a bicomponent technology, featuring the Husqvarna specific texture on the upper part. Side number plates are kept as close as possible to the frame and subframe concept for unrestrictive ergonomics.

The general seat line is slightly flatter compared to the old generation and the bodywork is slimmer. The side panels now work much better with young riders’ boots which allows them to grip the machine tighter with their legs when riding stood up. This inspires confidence and allows youngsters to ride with their full focus on the track ahead.

The bodywork including the seat can be raised to a higher position for taller children who outgrow the standard configuration.

Husqvarna Motorcycles side covers/number plates (2 in1), smaller plastic part can be removed as on full size models.

Graphics

Modelled after the full-size motocross bikes, the TC 50 features striking, Swedish-inspired grey and yellow livery. Additionally, the graphics are applied using an in-mold process to ensure the best durability and quality.

Rounded off is this neat looking beauty with many parts featuring as specific Husqvarna brand texture for the ultimate look and grip. (e.g., seat cover and tank spoiler with same texture as on full-size models).

Engine

The modern and compact engine features the latest in 2-stroke technology to offer class leading performance and rideability. By using a 3-shaft design, the crankshaft is positioned near the centre of gravity which not only benefits mass centralisation, but also creates the ideal intake angle into the reed valve to deliver top level performance. Additionally, the engine is fitted with an automatic centrifugal clutch which reduces the complexity for younger riders.

An independent cylinder casting allowed for a redesigned cylinder. With a peak power of 15 hp, the big advantage of the new engine is its wide and usable powerband which will benefit all levels of rider. Further improvements could be achieved with the flow-optimization and thermodynamics, the general packaging, and the total weight which has been reduced by 60 g. (new 666 g - old 726 g).

The TC 50 is now, for the first time, a real 50cc (49.9cc) model thanks to its increased stroke. In the past the model featured a 49.0cc cylinder, which is 2% less capacity when compared to the new generation.

Of course, ignition timings needed to be adapted to the new longer stroke and the ignition itself is also new and now digital.

The mounting concept of the crankshaft is now simplified and much easier in the rare case the engine will need to be opened.

Crankcases and engine covers

The crankcases have been designed to house the internal components of the engine in the perfect position to achieve the ideal centre of gravity at the lowest possible weight. The cases are manufactured using a high-pressure die cast production process, which results in a thin wall thickness while retaining exceptional strength and reliability.

Draining noses for liquids and added service markers on the engine (▲) clearly show where to use washers, making maintenance and servicing easier than in the past. Also, Nm markings clearly show how tight to tighten the corresponding bolts to avoid overtightening. Many of the bolts for the engine cases are the same length for faster assembly.

For the first time, the crankcase is machined in the crankshaft area which leads to a tighter tolerance between the crankcase and crankshaft.

Husqvarna Motorcycles specific clutch covers:

- Husqvarna brand logo and brand specific finish in a Beige Grey powder coating

Integrated into the new clutch cover is the clutch spring preload adjuster and offers the ability to check the oil level. A new ignition cover comes with an optimized labyrinth sealing concept to prevent water ingress.

Cylinder head

The redesigned combustion chamber inserts are now made from two separate parts.

As a result, heat conduction is significantly improved. Mixing up inserts from different Husqvarna Motorcycles models (e.g., TC 65) is not possible. Generally, the design follows the same logic as the full-size TC range which ultimately results in simplified maintenance.

Ignition

A new digital ignition finds its way onto the new TC 50 and offers much more power and longer durability over time.

Individual ignition timings over the whole rpm range (as on full size models) have been introduced. This is one of the significant advantages of the digital ignition, as it wasn’t possible with the old analog ignition set-up.

The ignition timings are all new as well. This of course was needed due to the revised engine layout, featuring the longer stroke and other updates.

Spark plugs

The TC 50 features a new spark plug from BRISK which is easier to remove and re-install during routine maintenance.

Carburettor

The well-known and proven Dell'Orto type PHBG 19 BS carburettor is unchanged from the previous generation. Inside, an updated setting was needed to make the new engine, exhaust, and air intake work perfectly to deliver strong and controllable power.

Exhaust

A completely new exhaust system, manufacturing using the same process as the full-size motocross machines improves the quality and performance. Thanks to the removal of welding seams on the inside of the exhaust pipe the flow is optimized which results in massive improvements when it comes to thermodynamics and ultimately, performance.

The silencer has been updated and now comes with a black anodized finish. On top of this visual change, a performance improvement comes from a much better sealing of the silencer end cap.

A new rubber connector between the header pipe and silencer improves sealing to maintain performance.

Clutch

A key feature of the TC 50 is the automatic centrifugal clutch. This allows young riders to ride without the complexity of operating a manual clutch and gearbox. The multi-disc clutch delivers precise and predictable power delivery across the RPM range and furthermore, can be set to suit rider preferences or track conditions without the use of any special tools.

The clutch system for the new generation has been reworked and received several major updates.

The clutch basket is reinforced, and the number of carriers/fins is increased. This leads to a better durability, wear, and consistent performance.

The high-quality sintered clutch discs remain while the gasket is now made from an improved rubbery material with a central core made from metal.

The clutch is also simpler to disassemble than in the past as torx bolts are now used instead of hexaganol head bolts.

Power reduction kits (Technical Accessories)

For absolute beginners the engine power can be reduced to a moderate and controllable 4 hp which is equivalent to the level three setting on the EE 5.

An additional power reduction kit offers 8 hp which is equivalent to the highest setting on the EE 5 for intermediate riding levels.

Cooling circuit

The cooling system has been significantly improved for 2024. The water pump concept now features a new diecast cover and TC 50 specific impeller. Both parts are carefully designed to work perfectly with the new cylinder and cooling circuit. All sealings come with the tightest tolerances possible for maximum efficiency.

Sprocket (front)

The front sprocket is now installed using a bolt like on the full-size models. The old lock ring is no longer required and the new solution is much safer and more durable.