Engine

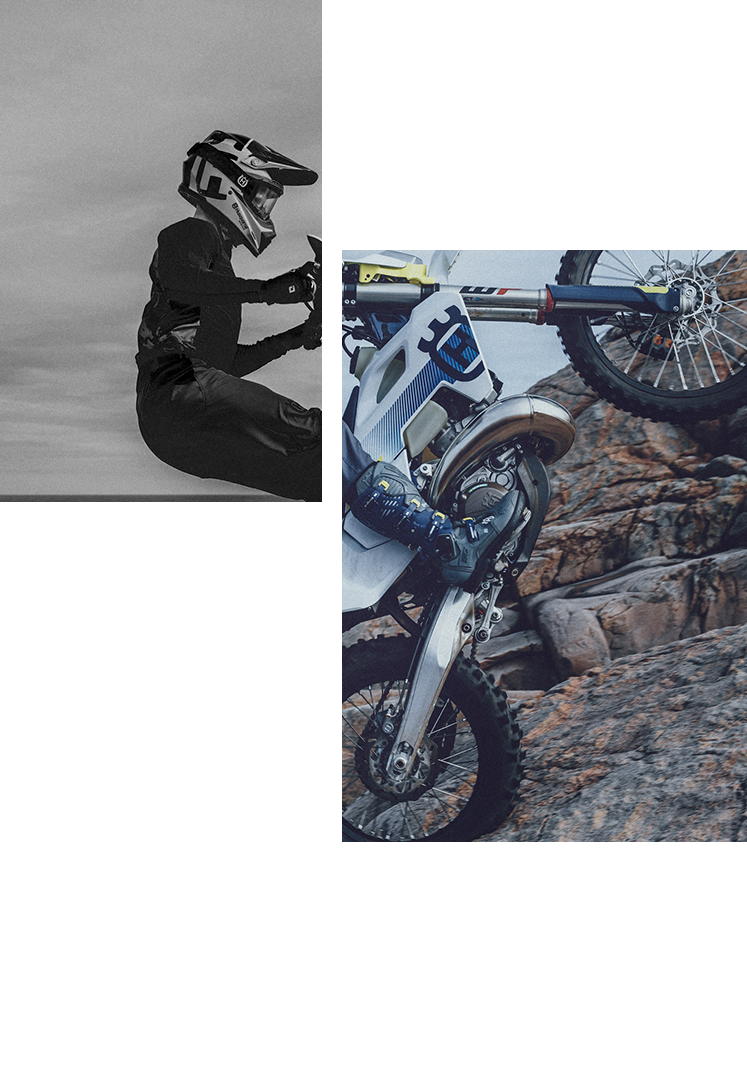

The FC 250 Rockstar Edition engine is tilted 2° backwards and therefore comes with a repositioned sprocket which is 3 mm lower compared to the previous generation. The total engine height has been reduced by 8 mm to improve mass centralisation and reduce weight.

Added service markers on the engine (▲) clearly show where to use washers, making maintenance and service easier than in the past.

All major components and shaft arrangements are carefully designed and placed to best suit the performance and handling characteristics of the machine, and an added benefit of this design is improved anti-squat behaviour from the whole chassis.

The 250cc engine is not only light at 26.11 kg, but also remarkably powerful with an overall output of more than 47 hp.

- Engine design → light and compact for optimised mass centralisation

- Low-friction design → reduces overall drag and vibration

- Outstanding high-revving performance engine → over 47 hp peak power and a 14,000 rpm rev limit

- Easy serviceability of engine internals with added service markers

Cylinder head

The DOHC cylinder head features finger followers with a DLC (Diamond Like Carbon) coating resulting in minimal friction and optimal performance. These actuate large titanium valves (32.5 mm intake, 27.5 mm exhaust) which at the 14,000-rpm limit, open and close multiple times every second to deliver the fuel/air mixture into the combustion chamber for optimal power throughout the rev-range.

The 27.5 mm exhaust valve is a result of the bore/stroke ratio, delivering an optimised gas flow. Valve timings have been adapted to the valve measurements, working in perfect harmony with the camshaft.

For easy serviceability and maintenance work within the engine, the camshaft bearing bridge is screwed and thus increases stiffness. Also, the head gasket comes with a ‘stopper design’, reducing sealing gap oscillations caused by gas force.

- DOHC cylinder head → Advanced durability and serviceability

- Finger followers with DLC coating → reduce friction and guarantee optimal performance

- Large titanium valves (32.5 mm intake, 27.5 mm exhaust) with 27.5 mm exhaust valve → optimized gas flow

- Camshaft → adapted valve timing to valve measurements

- Camshaft bearing bridge increasing stiffness and improving serviceability (screwed design)

- Cylinder head gasket with stopper design → reducing sealing gap oscillations caused by gas force

Cylinder and piston

The 81 mm bore cylinder houses a forged bridged-box-type piston made by CP with an extremely light weight of only 150 g. Both the cylinder and piston are professionally engineered from high-strength aluminium resulting in outstanding performance and reliability. The 48.5 mm stroke and the compression ratio of 14.5:1 provide added torque and peak performance.

Thanks to the CFD optimised combustion chamber, the inlet port could be smaller in section resulting in increased engine responsiveness.

- 81 mm bore and 48.5 mm stroke (2022 = 78/52.3 mm)

- Large 81 mm bore and larger diameter exhaust valves → high-revving, quick response

- CFD optimised combustion chamber → smaller inlet port for improved engine responsiveness

- Compression ratio of 14.5:1 → outstanding torque and peak power

- Forged bridged-box-type piston → high performance and reliability

Crankshaft

The crankshaft is designed to offer the best possible performance while being perfectly positioned in the engine cases to centralise oscillating masses for optimal handling. The plain big-end bearing features two force-fitted bearing shells ensuring maximum reliability and durability, guaranteeing long service intervals of 90 hours.

- Plain big-end bearing with force-fitted bearing shells → increased durability and service intervals

- Friction bearing on the counter-balancer shaft → increased durability

Crankcases

The FC 250 Rockstar Edition engine is designed with mass centralisation and weight reduction as the two main criteria. As a result, the crankcases have been designed to house the internal components of the engine in the perfect positions to achieve the ideal centre of gravity at the lowest possible weight. Engine mounting points are the same as on the FC 450 Rockstar Edition engine.

The casings are manufactured using a high-pressure die-cast production process, resulting in thin wall thickness while retaining exceptional strength and reliability.

- Light and compact crankcases → optimised mass centralisation

- Optimized engine mounting points (as on FC 450 Rockstar Edition)

- High-pressure die-cast production process → thin walls for reduced weight while maintaining strength

Gearbox

Produced by Pankl Racing Systems, the 5-speed gearbox is designed to be extremely light and durable while featuring a 250cc-specific ratio (24:72). The optimized shift shaft reduces the operating forces required for gear changes with a Quickshift sensor on the shift drum ensuring smooth upshifts. The function can be activated/deactivated via the QS button on the Map Select Switch, located on the left side of the handlebar.

The shift fork has a low-friction coating for smoother shifting, while the gear lever is designed to prevent dirt build-up and ensure perfect gear selection in all conditions. An advanced gear sensor allows for specific engine maps to deliver the best possible performance in each gear.

- 5-speed gearbox by Pankl Racing Systems → 250cc-optimised transmission ratio (24:72) and exceptional durability and effortless shifting

- Optimized shift shaft → reduced operating force required for gear changes

- Integrated Quickshift sensor on the shift drum allows clutchless upshifts → seamless shifting function can be activated/deactivated with Map Select Switch

- Integrated gear sensor → specific engine maps for each gear

DS clutch

The FC 250 Rockstar Edition features a Diaphragm Steel (DS) clutch. The exclusive characteristics of this system include a single diaphragm steel pressure plate instead of traditional coil springs.

The clutch basket features the same design as the FC 450 Rockstar Edition but adapted to the transmission ratio. It is a single-piece, CNC-machined steel component that allows the use of thin steel liners and contributes to the compact design of the engine.

- Clutch basket with same design as FC 450 Rockstar Edition → adapted for transmission ratio

- DS clutch → lightweight with consistent action and exceptional durability