01. Unrivalled power

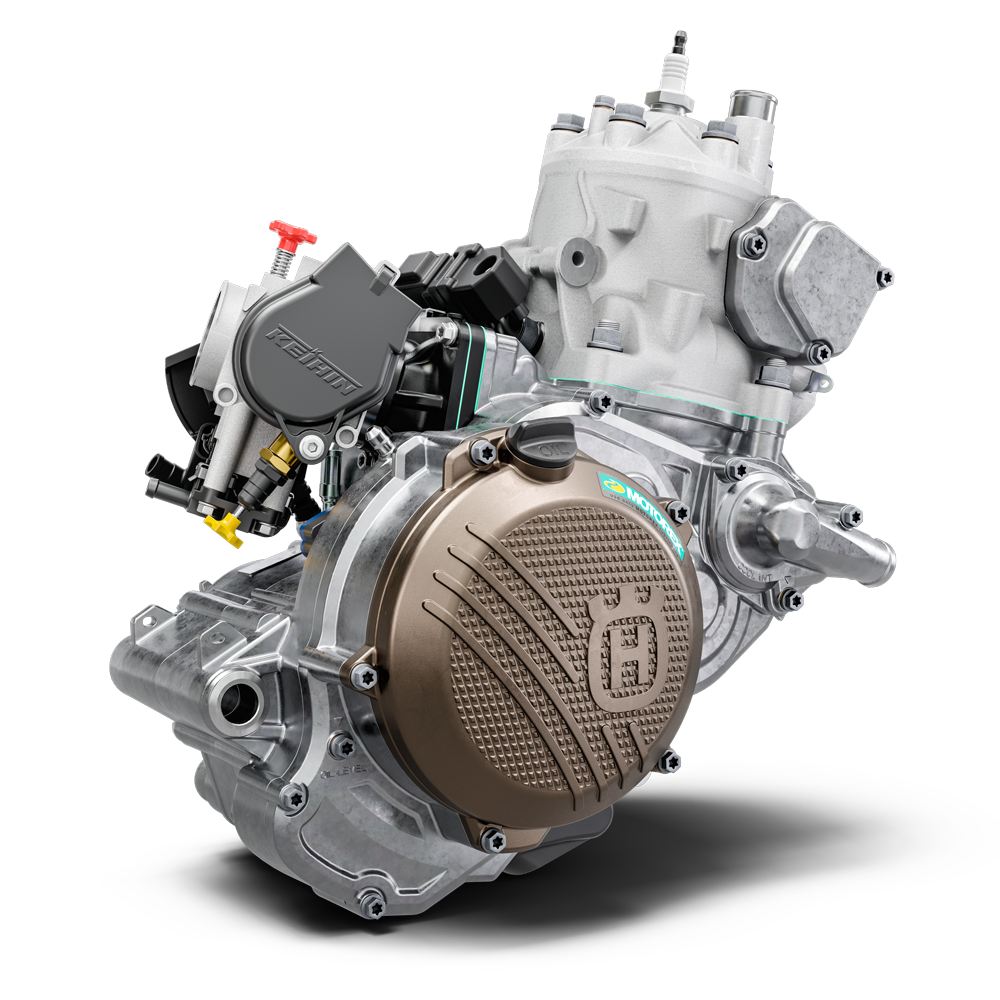

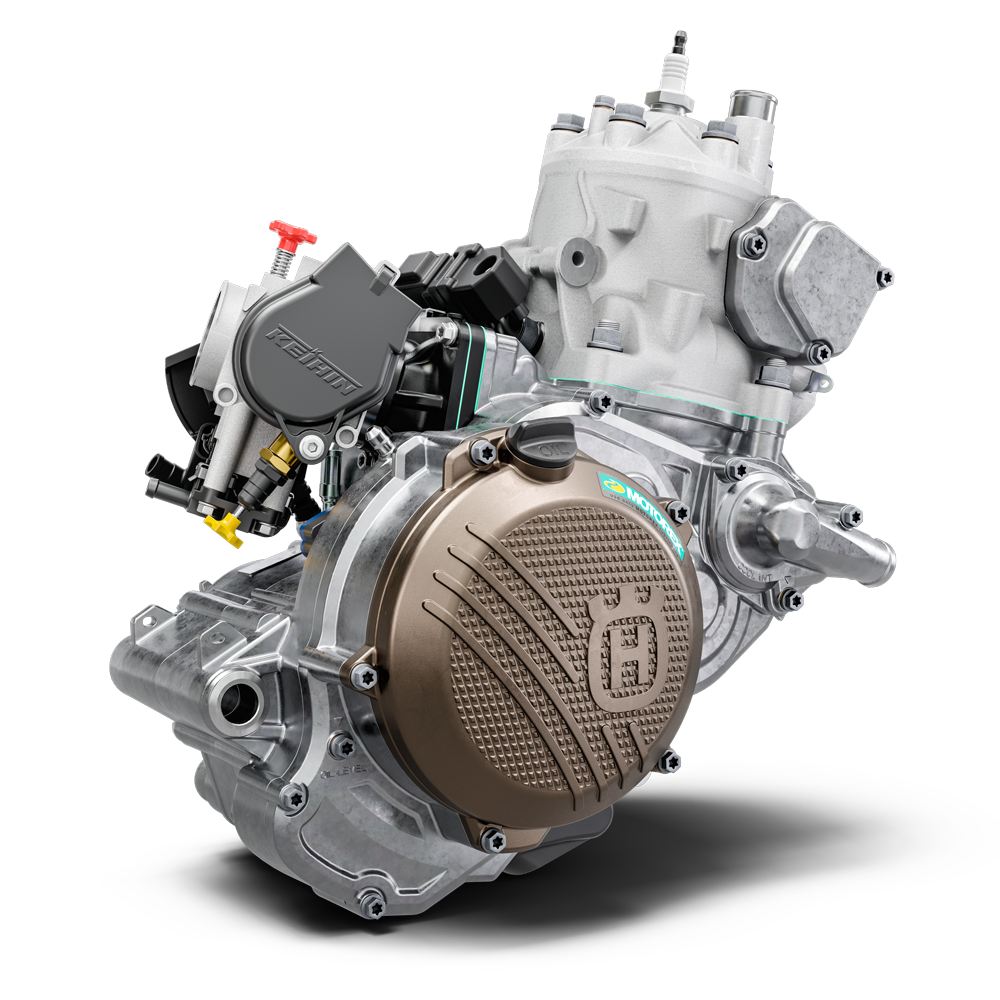

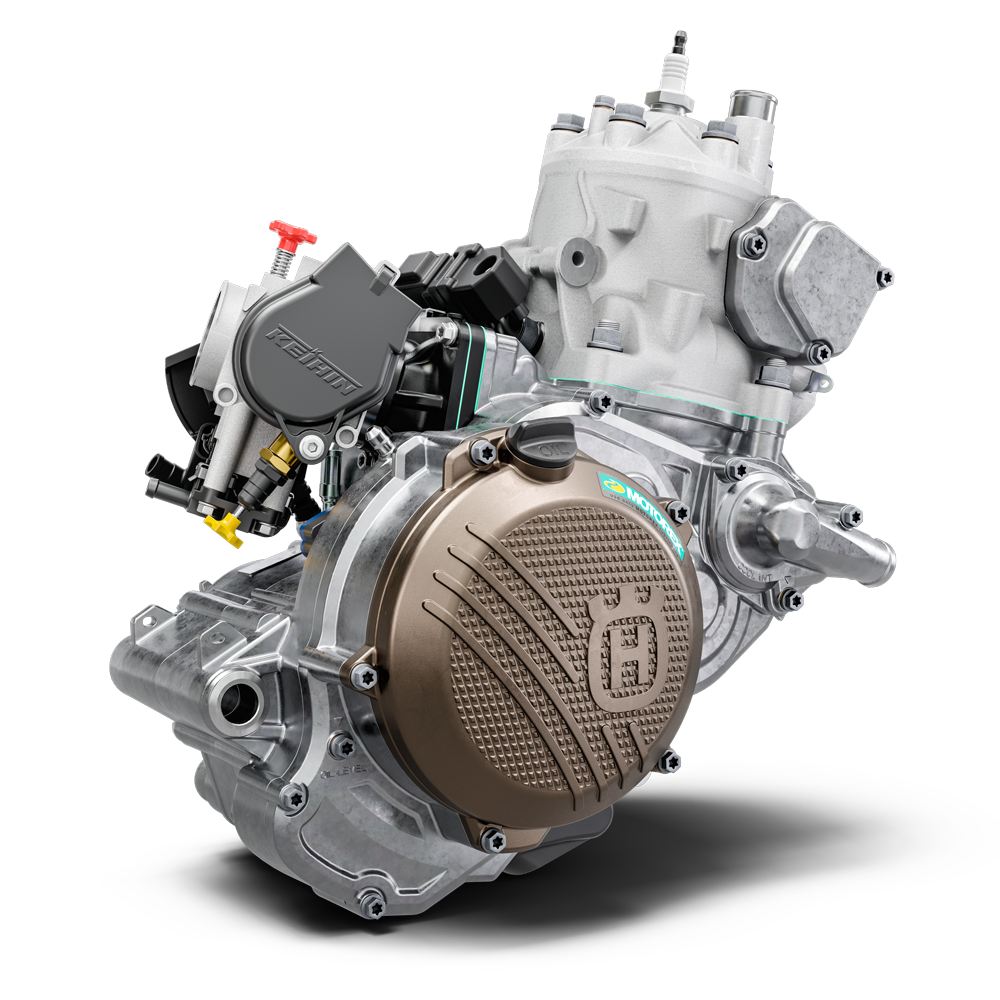

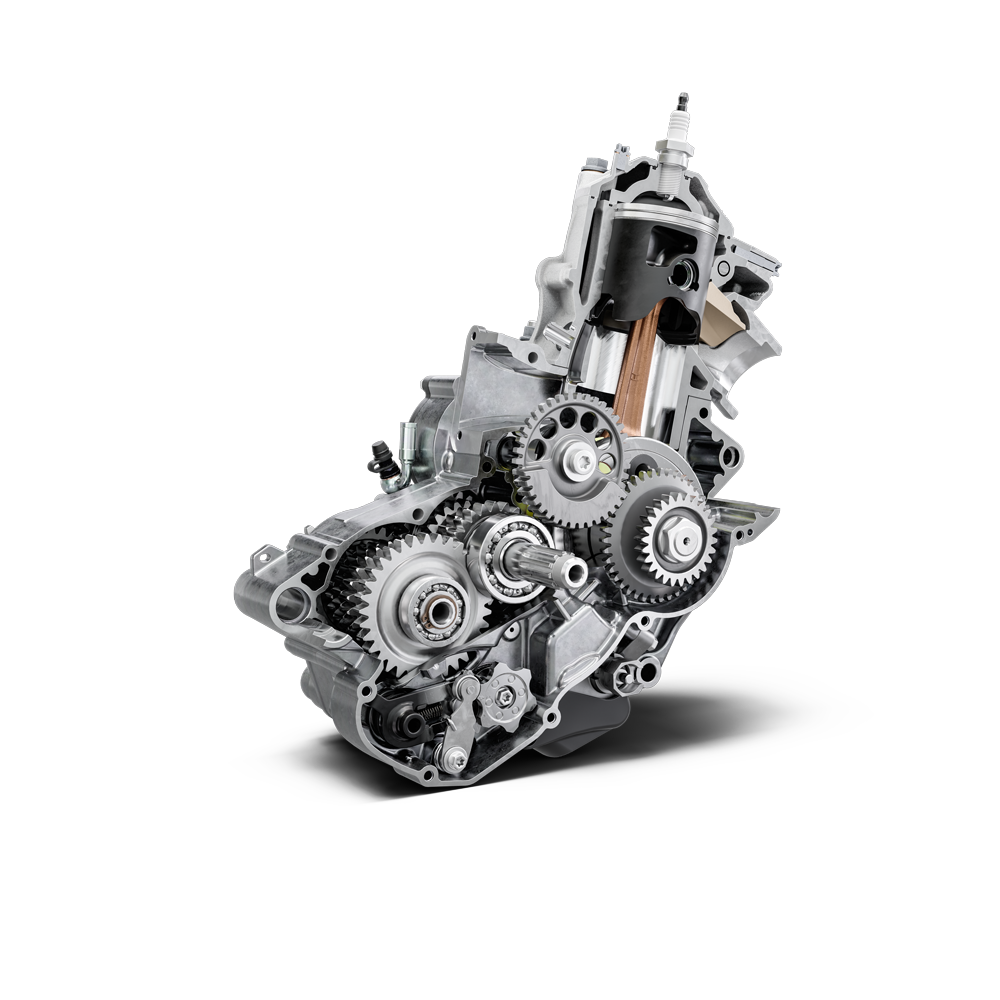

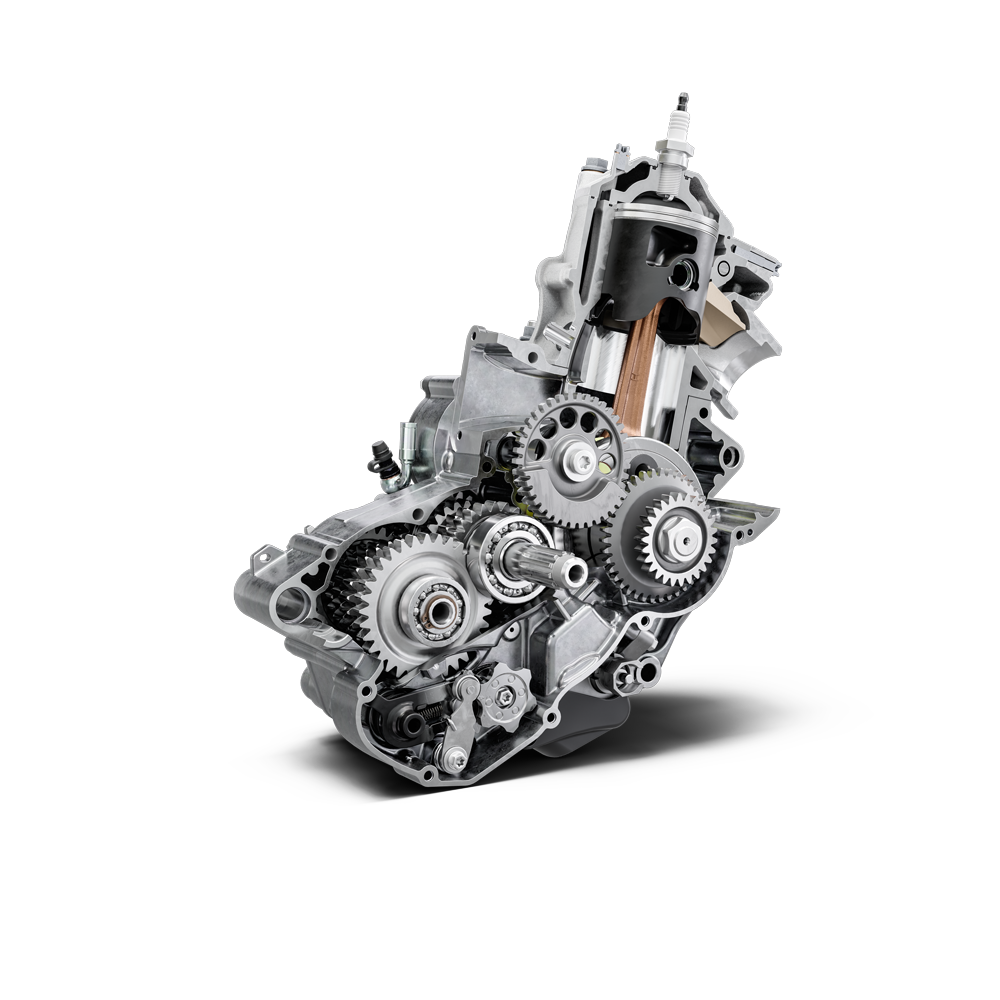

Engine

Delivering class-leading power, the TE 300 engine is built with maximum performance in mind. Thanks to the Throttle Body Injection (TBI), the engine delivers impressive torque while maintaining its high-revving two-stroke character to offer all riders a versatile power delivery. Designed to be compact to reduce overall weight, the engine tips the scales at just 54.2 lb (24.6 kg). Additionally, the shaft arrangements inside the TE 300 engine are precisely positioned for greater mass centralization while a counter balancer shaft reduces vibration.

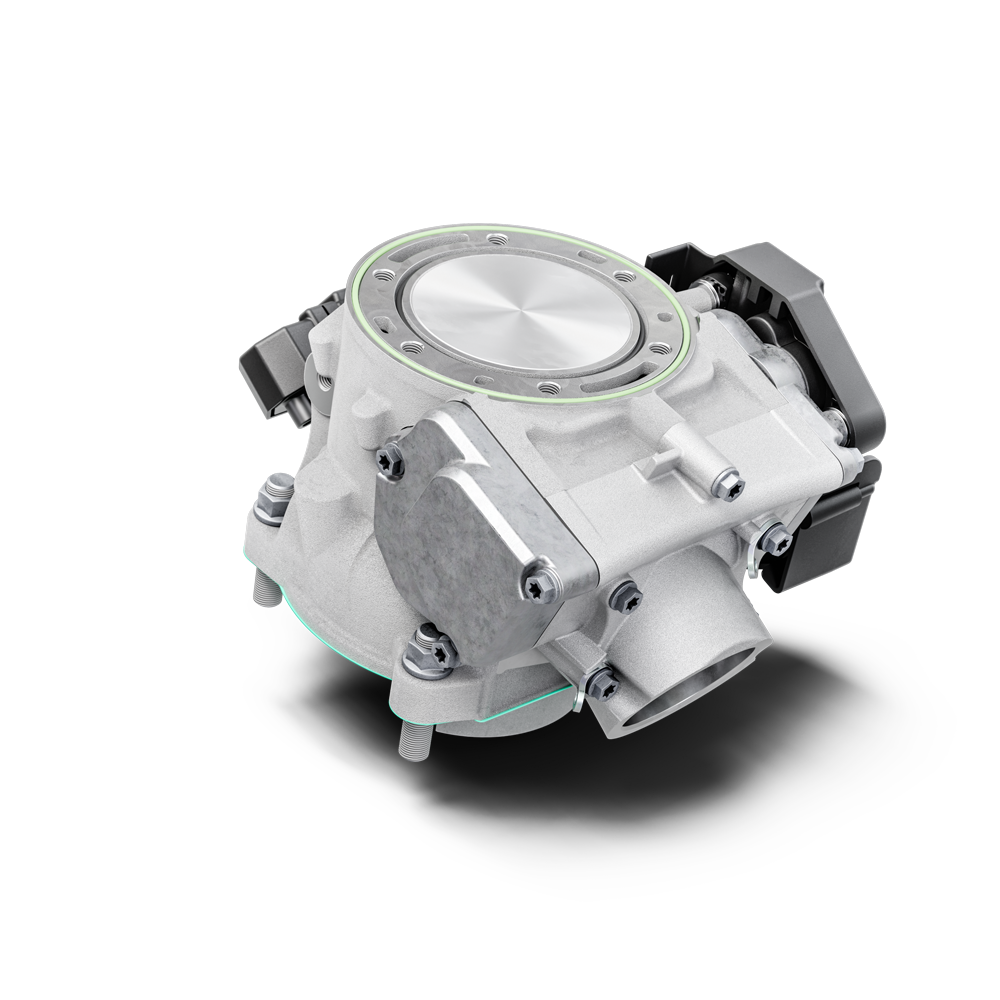

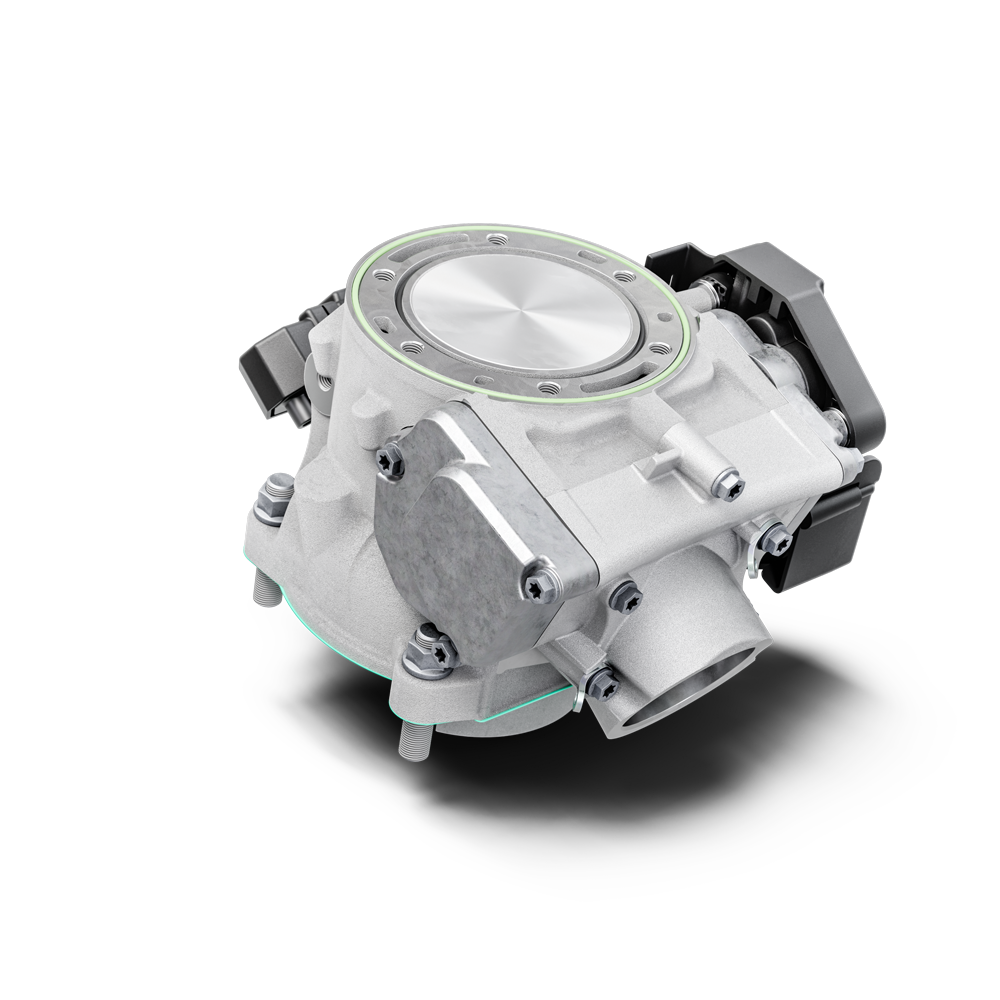

Cylinder

With the introduction of Throttle Body injection (TBI) on the TE 300, the 72 mm bore cylinder now features an innovative electronic exhaust control system, which manages the opening of the lateral exhaust ports after the main exhaust port opens for maximum power delivery. Together with a machined finish on the upper contour of the exhaust port that ensures accurate port timing, unrivalled engine performance is assured.

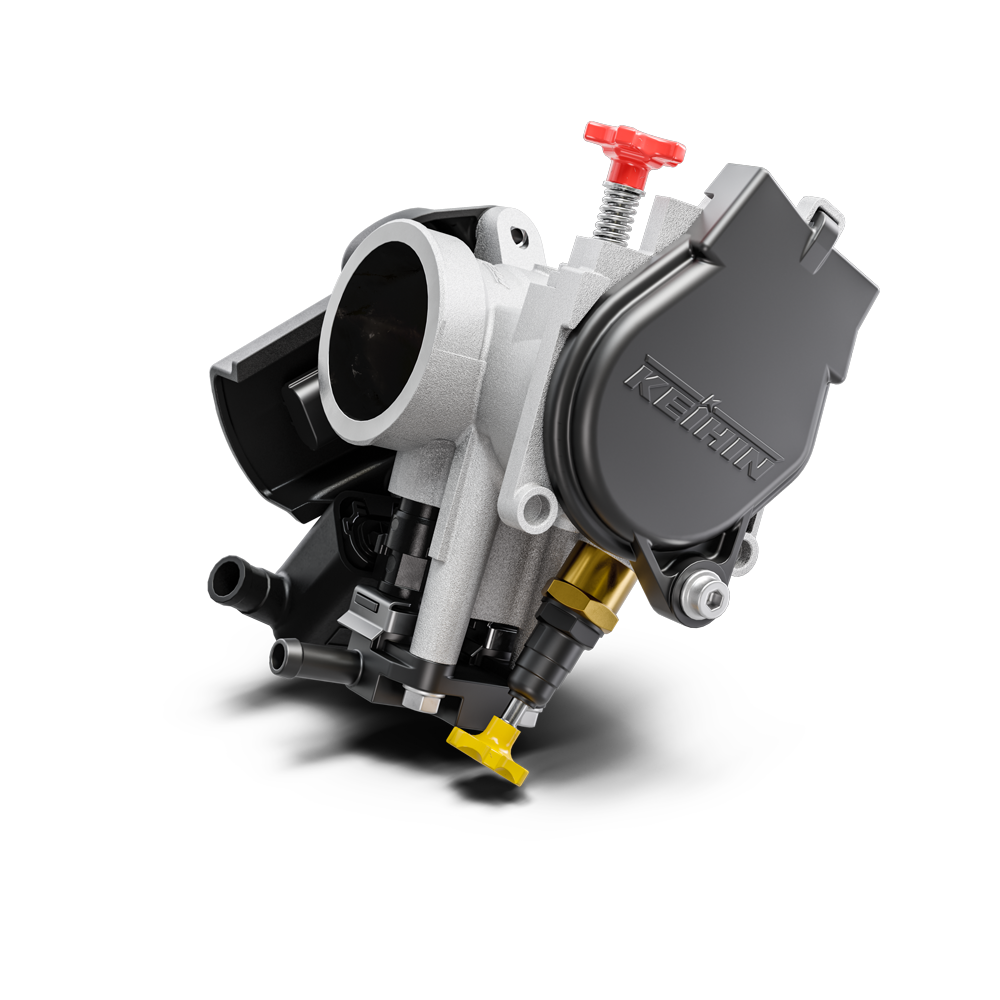

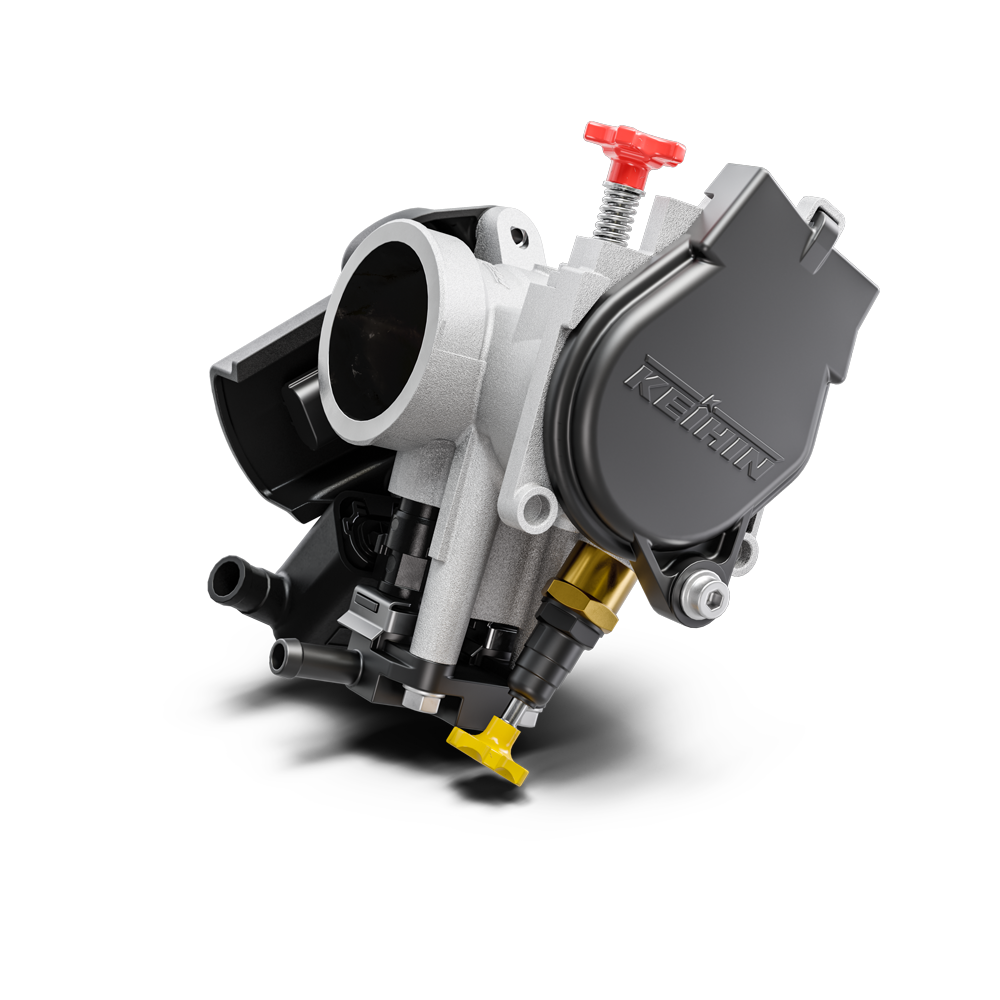

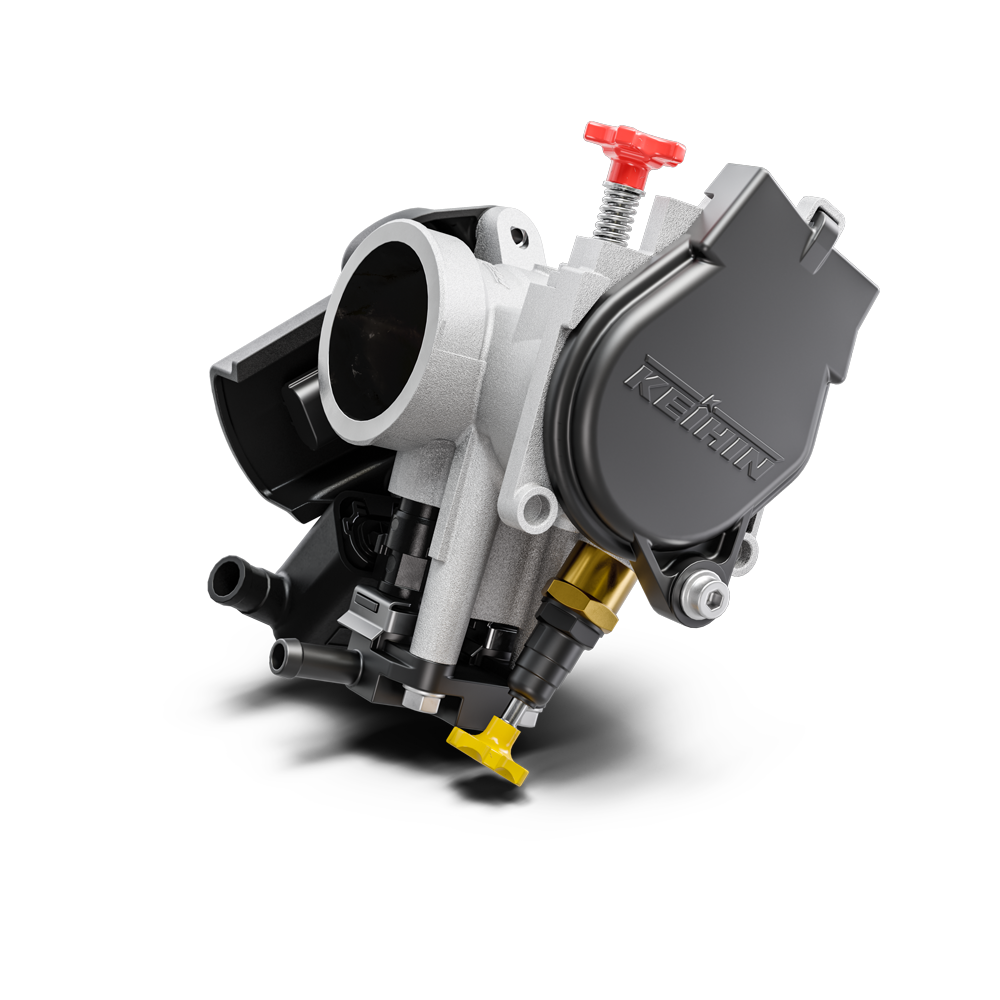

Throttle body

The TE 300 uses a 39 mm throttle body with dual injectors positioned to optimise flow for more immediate throttle response and exceptional rideability. Idle is controlled by the throttle valve, with one low load injector and one top feed injector ensuring maximum performance. Additionally, a Throttle Position Sensor (TPS) offers reliable cold starting with the throttle valve now pivoting on ball bearings for a smoother throttle action.

Oil tank

An electronic oil pump feeds vital 2-stroke oil into the engine. It is located just below the oil tank and feeds the oil via the reed cage, meaning the oil is only mixed with air at this stage. The pump is controlled by the EMS and delivers the optimal amount of oil according to the current RPM and engine load. The oil tank is connected to a filler hose which runs through the upper tube of the frame to a filler cap conveniently located for easy refills.

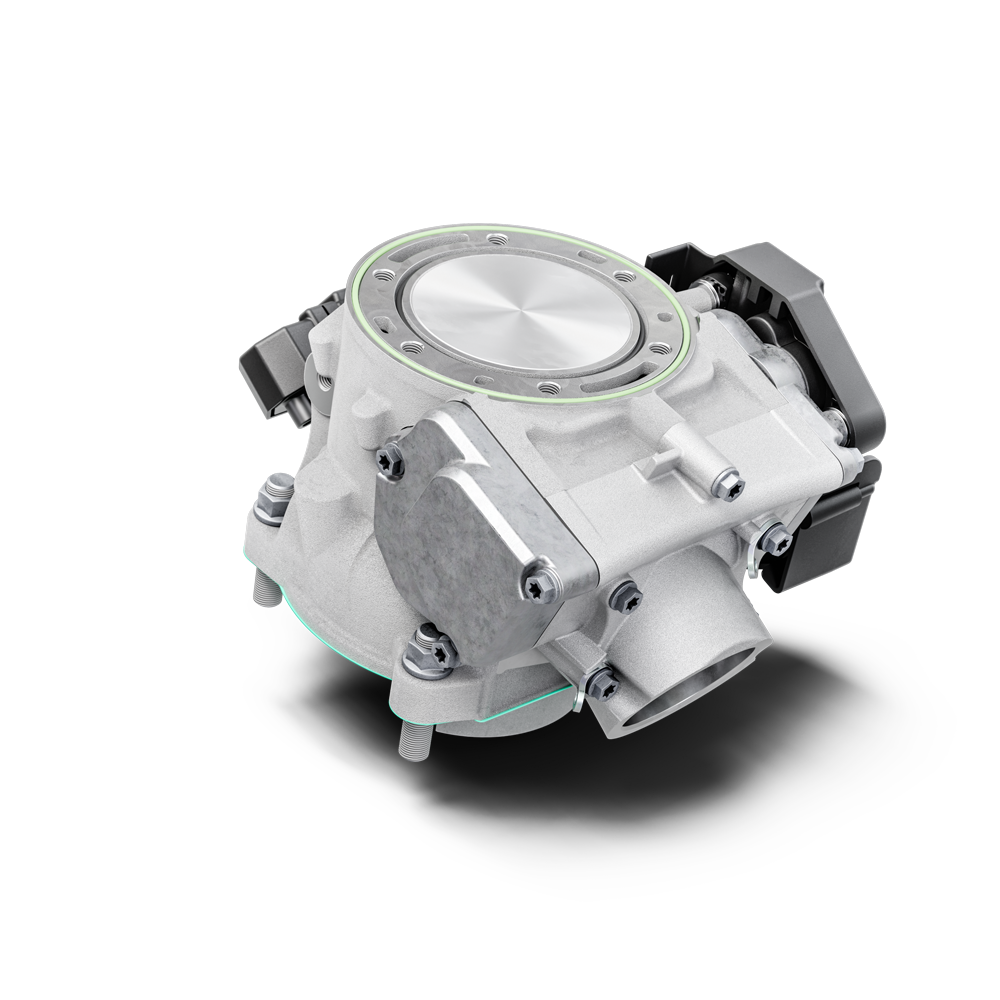

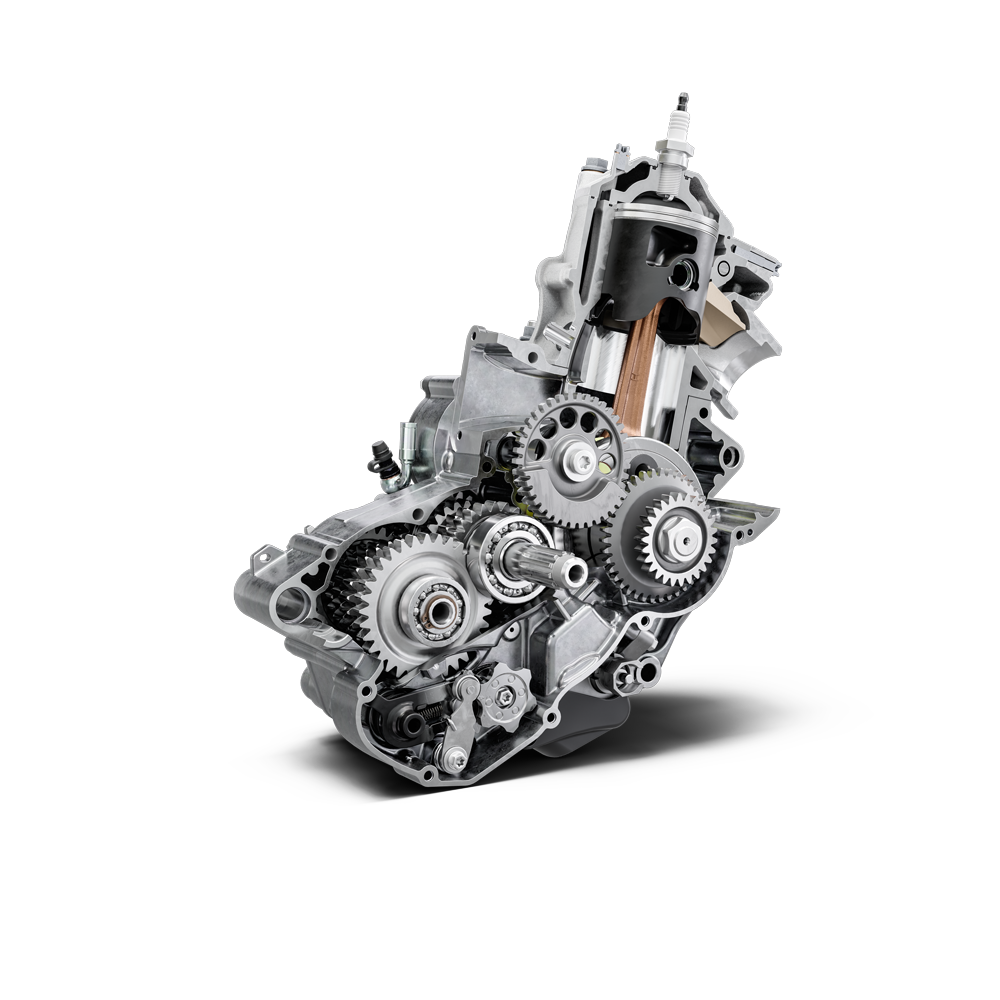

Crankcase

Designed to be low in weight without sacrificing strength or reliability, the new crankcases are made using a high-pressure die cast production process to create a thin-wall design. To centralise engine mass, the shaft arrangements are precisely positioned to harness rotating masses at the ideal centre of gravity.

Exhaust

Tailored specifically for the TE 300 using an innovative 3D design process, the header pipe ensures unrestricted performance and offers improved ground clearance to reduce the risk of impact damage out on the trail. The silencer also features an aluminium mounting bracket and advanced internal construction for excellent noise damping and weight saving.

Engine

Cylinder

Throttle body

Oil tank

Crankcase

Exhaust