01. Faster and wiser

Engine

The FX 350 engine is designed to deliver maximum performance with all major engine components and shaft arrangements positioned to enhance overall handling. Weighing just 27.2 kg, the 350 cc 4-stroke engine centralises mass and aids the anti-squat behaviour of the whole chassis.

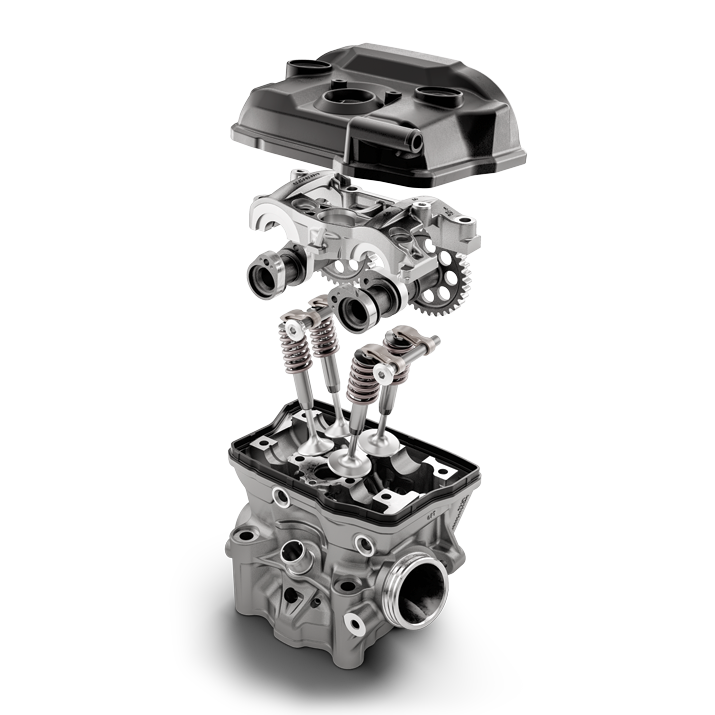

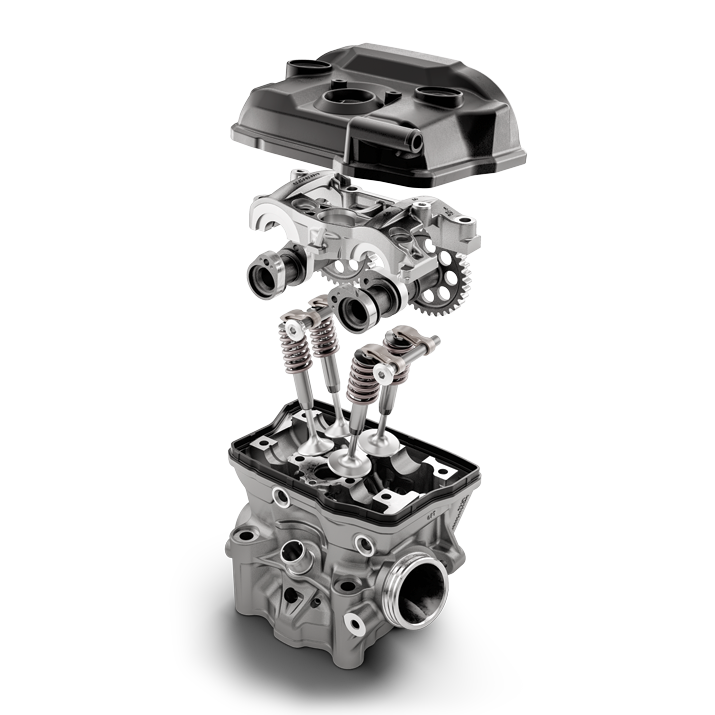

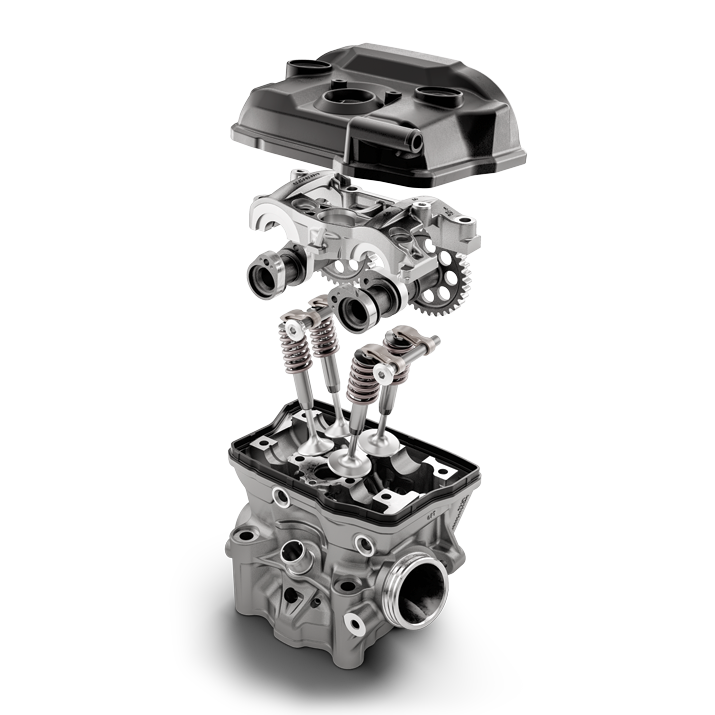

Cylinder head

The DOHC cylinder head offers improved durability and serviceability, with diamond-like carbon (DLC) coated finger followers to guarantee minimal friction and optimal performance. These actuate large titanium valves, 36.3 mm for the intake and 29.1 mm for the exhaust, which optimise gas flow for strong, usable power across the rev-range, all the way up to the 13,400 rpm limit. Valve timings work in perfect harmony with the camshaft, which features a bearing bridge design for stiffness and easy serviceability.

Cylinder and piston

An 88 mm bore and 57.5 mm stroke cylinder is professionally engineered from high-strength aluminium for maximum reliability and houses the high performance forged bridged-box-type piston from CP. The compression ratio is 14.6:1 for exceptional torque and peak power.

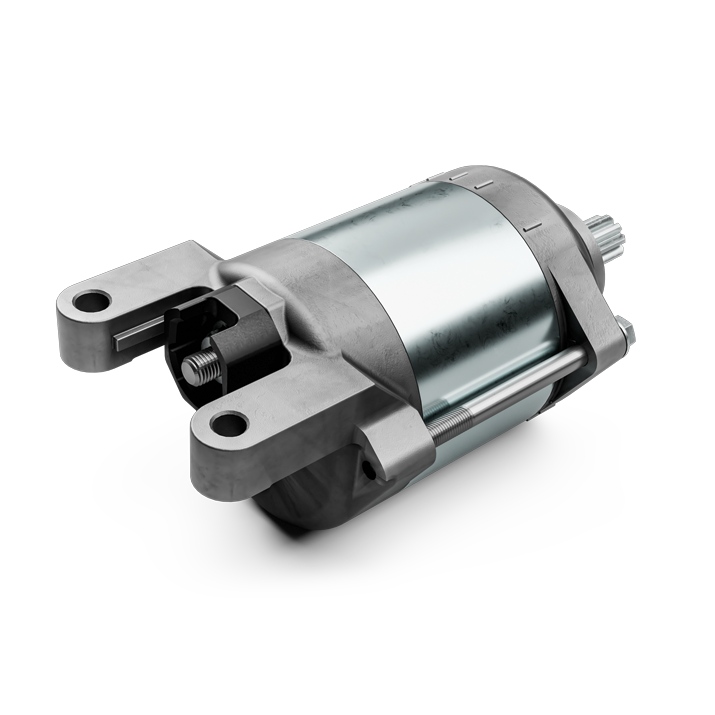

Crankshaft

At the heart of the high-output, high-revving FX 350 engine is the crankshaft. This features a plain big end bearing rotating on two force-fitted bearing shells for maximum reliability and guarantees long service intervals of 90 hours.

Crankcases

Designed for optimised mass centralisation, the FX 350 crankcases house all internal components in the perfect position to achieve the ideal centre of gravity. Manufactured using a high-pressure die cast production process, the result is a thin, exceptionally strong wall thickness at the lowest possible weight.

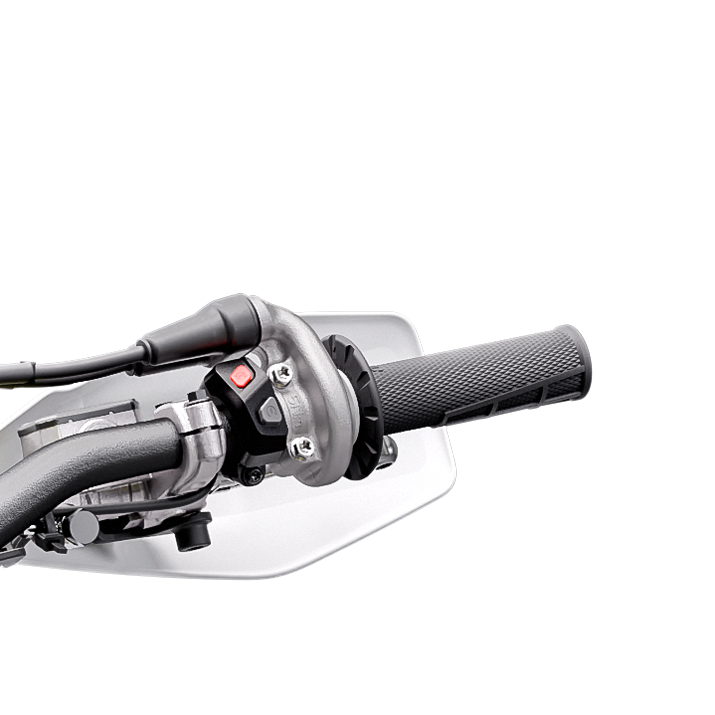

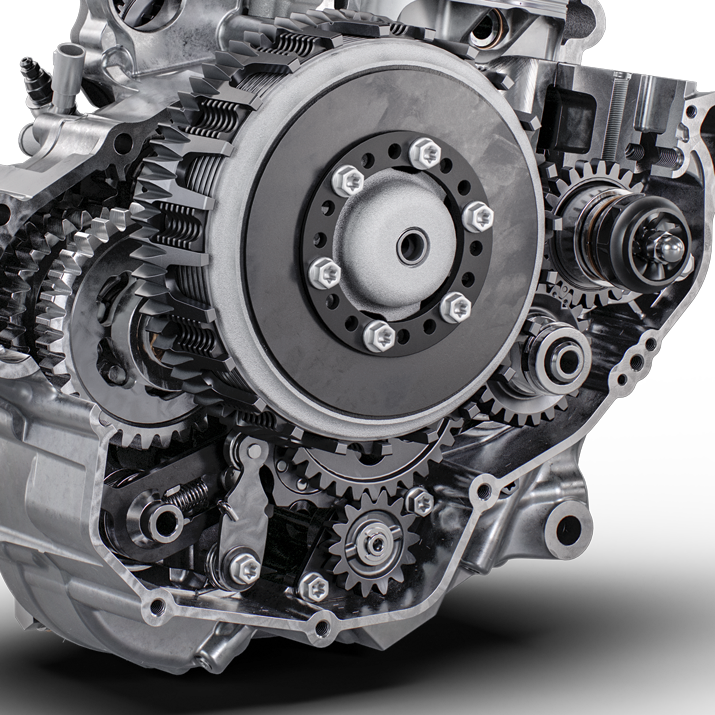

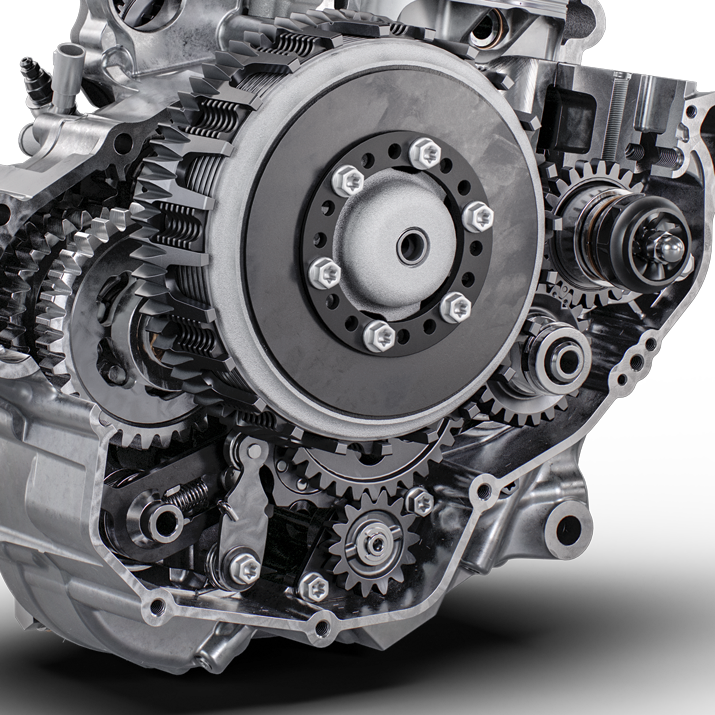

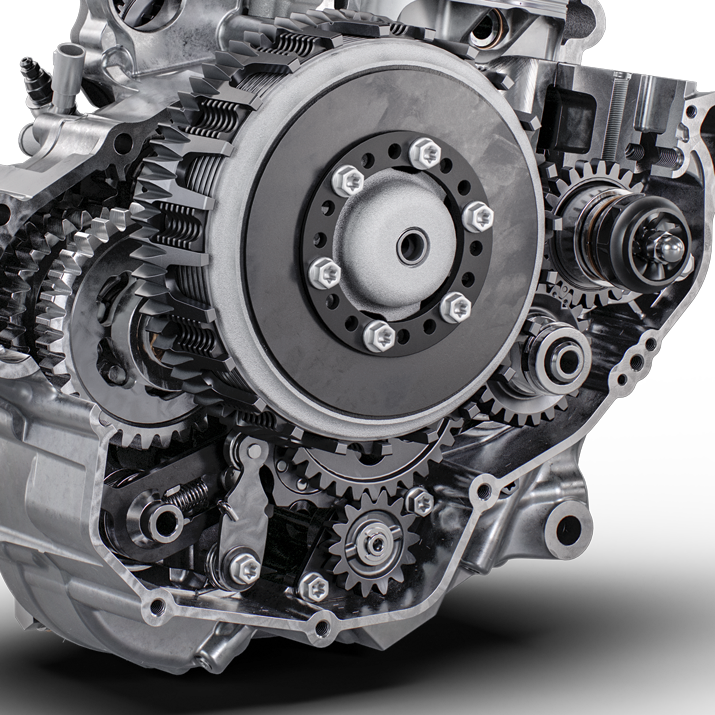

DS clutch

The FX 350 features a diaphragm steel (DS) clutch. Engineered from a single piece of CNC-machined steel, the clutch basket allows the use of thin steel liners that contribute to the compact design of the engine.

Gearbox

The 6-speed gearbox is manufactured exclusively by Pankl Racing Systems to ensure high durability and reliability. The shift drum and fork are designed for optimal leverage, ensuring smooth and precise gear changes in both upshifts and downshifts.

Engine

Cylinder head

Cylinder and piston

Crankshaft

Crankcases

DS clutch

Gearbox