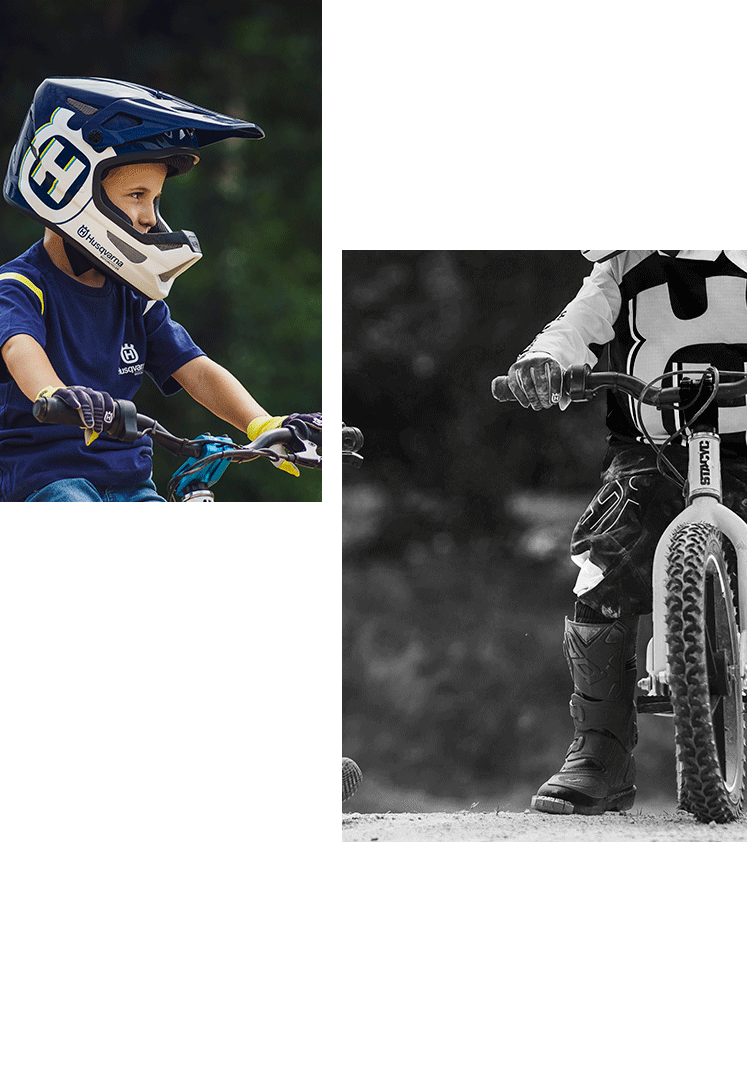

My first and only motocross bike was of course a Husqvarna, developed from the Dream Machine, which had first seen the light of day back in 1953. Despite good intentions, I never became successful on the track, but I remember as a kid dreaming of reaching the top of this gruelling sport. My neighbour had bought a used Silver Arrow, which I had the privilege of trying out in the dark woods around the western Stockholm area where I grew up.

Since the Dream Machine never sold to expectations, a new motorcycle was introduced in January 1955, stealing the name "Silver Arrow" from Mercedes successful four-wheeled racers. It was sales director Harald Carlström who baptised this embryo, since he was both a motorsport man and drove a Mercedes. The newcomer had exactly the right styling to tempt many a youngster to become a motorcyclist over the next decade. Actually, the Huskvarna factory benefitted over almost twenty years from income and developments that could be traced back to the Silver Arrow. A common joke was that the weapons factory reloaded its guns from releasing a silver-plated arrow to shooting a silver bullet through the air. All in all, 11,300 units were produced between 1955 and 1965 in the province of Smaland, before sales then stopped.

Since the Dream Machine never sold to expectations, a new motorcycle was introduced in January 1955, stealing the name "Silver Arrow" from Mercedes successful four-wheeled racers. It was sales director Harald Carlström who baptised this embryo, since he was both a motorsport man and drove a Mercedes. The newcomer had exactly the right styling to tempt many a youngster to become a motorcyclist over the next decade. Actually, the Huskvarna factory benefitted over almost twenty years from income and developments that could be traced back to the Silver Arrow. A common joke was that the weapons factory reloaded its guns from releasing a silver-plated arrow to shooting a silver bullet through the air. All in all, 11,300 units were produced between 1955 and 1965 in the province of Smaland, before sales then stopped.