01. Faster and wiser

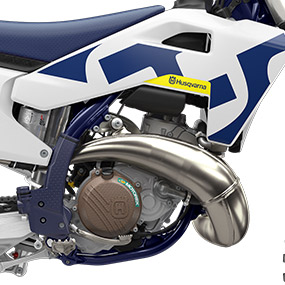

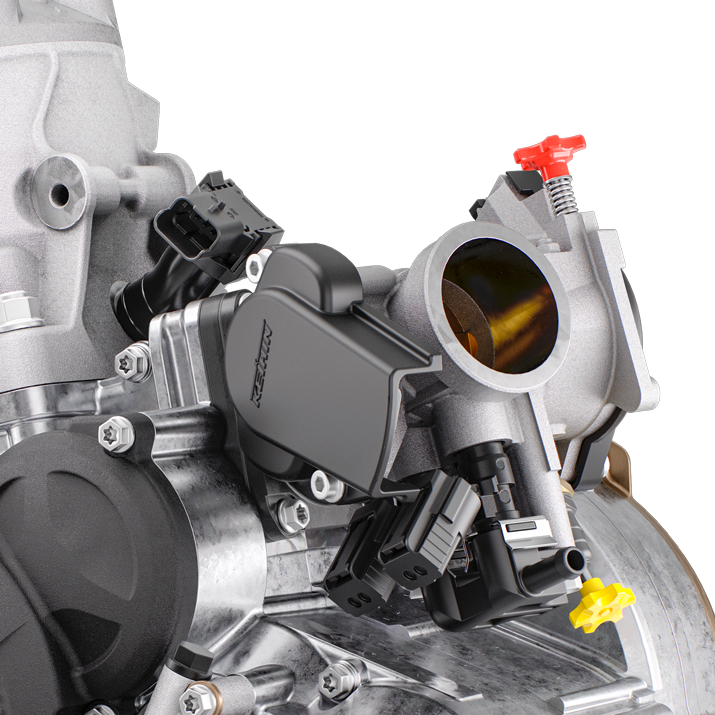

Engine

The TC 250 engine is at the pinnacle of 2-stroke performance and weighs just 52.6 lb (23.9 kg). Complete with the latest technical innovations, the TC 250 comes with electronic fuel injection (EFI) which reduces running costs, removes the need for jetting changes, and ensures reliability. The addition of electric start adds to the simplicity of this popular model, and guarantees fast starting in all situations.

Cylinder

The cylinder has a 66.4 mm bore but with the introduction of EFI, the traditional powervalve is replaced with an electronic exhaust control system. This highly innovative technology manages the opening of the lateral exhaust ports before the main exhaust ports open to deliver strong, controllable power. The upper contour of the exhaust port features a machined finish for improved port timing and unrivalled performance.

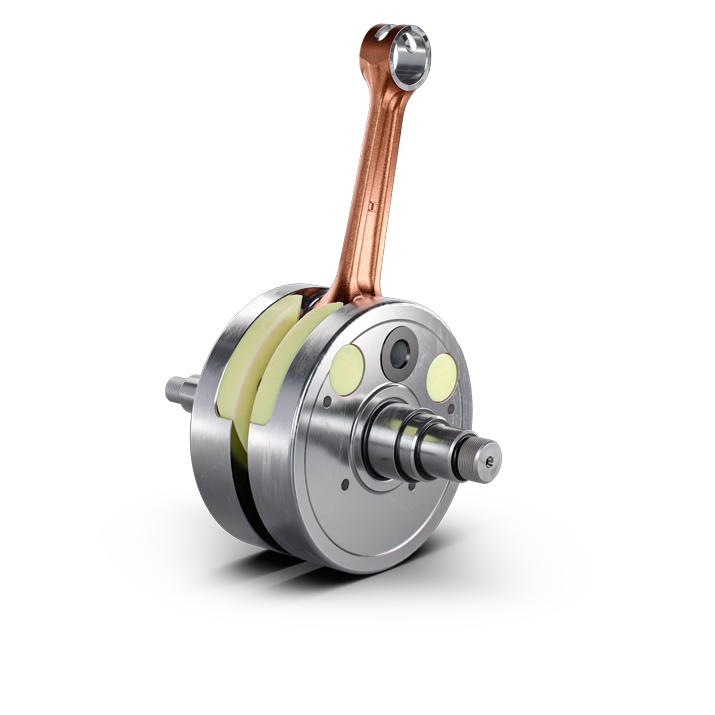

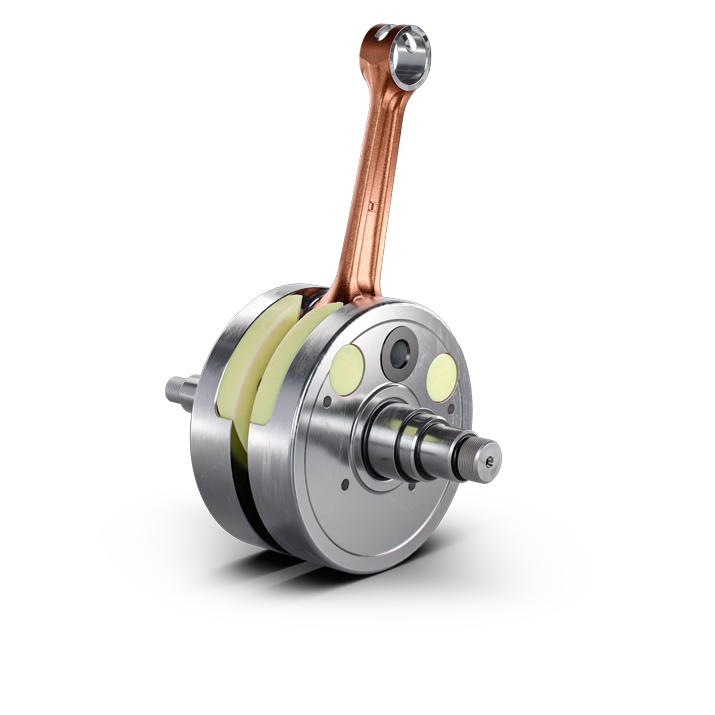

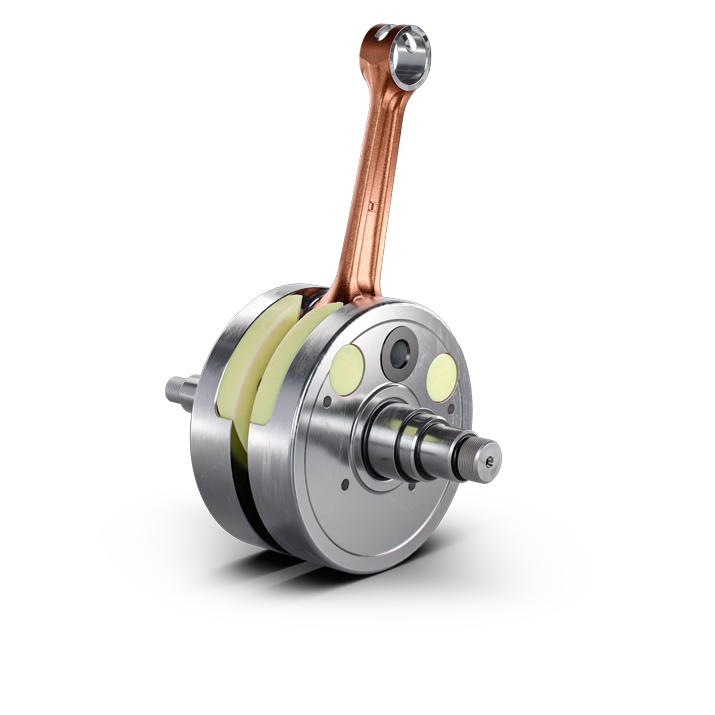

Crankshaft

The crankshaft is designed with weight reduction in mind to increase throttle response. The perfect balance of rotating masses is achieved by balancing the weights of the crankshaft flywheel, the rotor, and the counter balancer shaft.

Crankcases

High-pressure die cast production processes allow for the crankcases to be manufactured with a thinner wall thickness to keep the overall weight to a minimum, and to position the shaft arrangements perfectly for optimized mass centralization. This clever design aids the overall balance and agility of the TC 250 while the symmetrical engine mounts aid handling by contributing to the flex characteristics of the chassis.

Counter balancer shaft

The TC 250 features an innovative laterally mounted counter balancer shaft. This shaft significantly reduces engine vibration, resulting in a smoother and more comfortable ride.

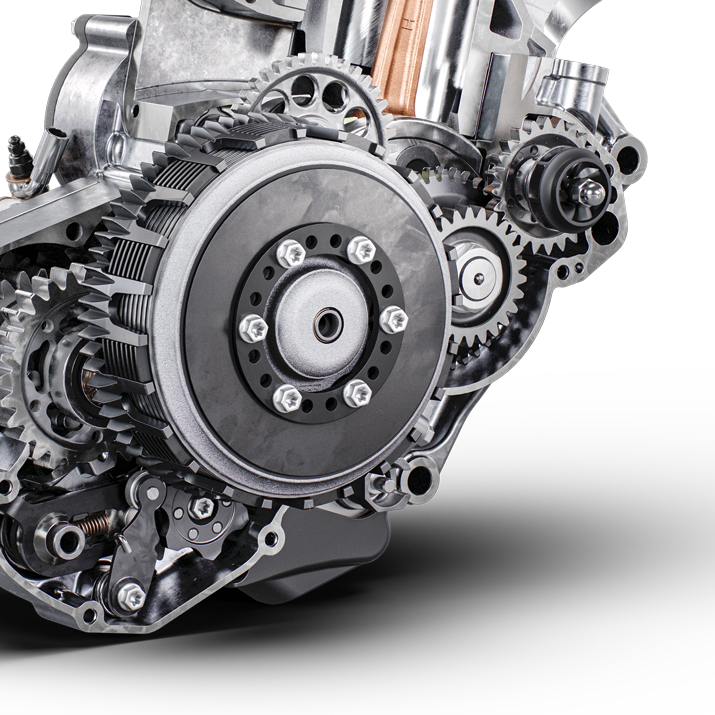

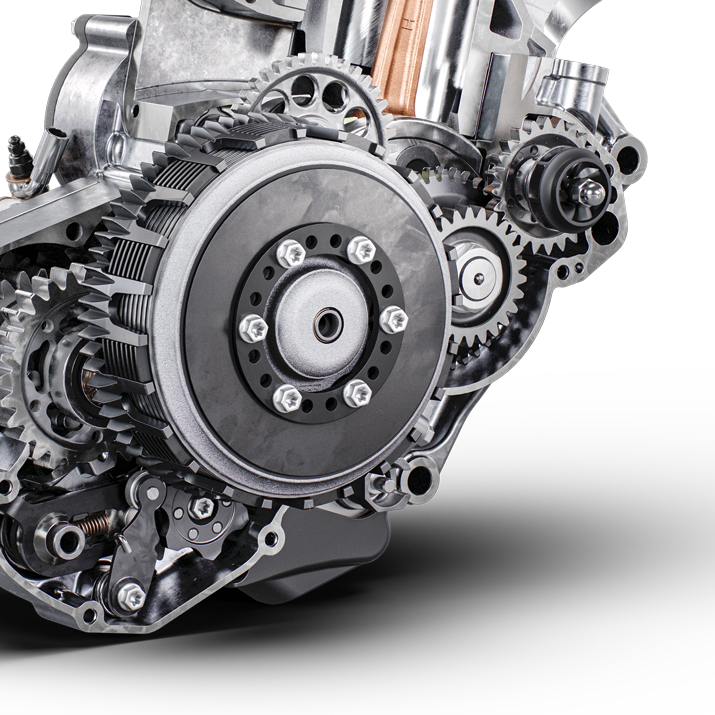

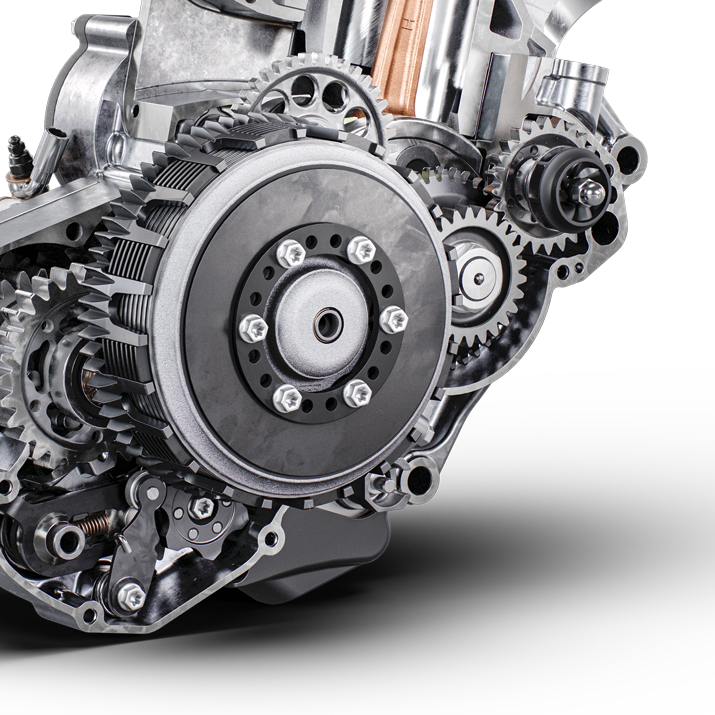

DDS clutch

The damped diaphragm steel (DDS) clutch fitted to the TC 250 is unique as a single diaphragm steel pressure plate is utilized instead of traditional coil springs. Housed inside a CNC machined steel basket, the overall clutch design contributes to the compact engine layout and features a damping system for improved traction and durability.

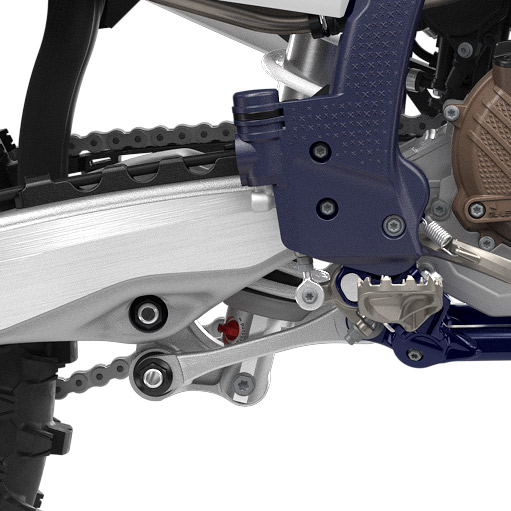

Gearbox

The TC 250 features a 5-speed gearbox manufactured exclusively by Pankl Racing Systems for the highest level of durability and ensures smooth and precise shifting. In addition, the gear lever tip design offers improved leverage and prevents dirt build-up, even in the toughest conditions.

Engine

Cylinder

Crankshaft

Crankcases

Counter balancer shaft

DDS clutch

Gearbox